The term hydrostatic refers to the fundamental concept we hold dear in fluid power, which is that confined hydraulic fluid under pressure exists in equilibrium and balance. Although hydraulic fluid does no more than hold objects stationary without the active application of force through a pumping device, the concept is entirely different than hydrodynamics, which […]

Engineering Basics

How do I know I’ve oversized my pump?

By Josh Cosford, Contributing Editor Oversizing your hydraulic pump is a relatively common error by beginner fluid power professionals or, more likely, entirely untrained individuals tasked with maintaining machinery. Everyone wears many hats these days, so don’t take it personally if you’ve inherited a role that requires skills above your pay grade. More than once […]

Fluid power at sea

Learn how hydraulics are used in maritime vessels and why hydraulics is the technology of choice. By Josh Cosford, Contributing Editor Hydraulics have played a vital role in various industries, and the marine sector is no exception. From small pleasure boats to large ocean liners, hydraulics are extensively used in a wide range of marine applications […]

How do you select the right hydraulic motor for your application?

Hydraulic motors are rotary actuators that convert hydraulic energy into mechanical torque. Using the pressure and flow provided by the hydraulic pump, hydraulic motors rotate to pull, drive or winch external loads on various hydraulic machines spanning construction equipment to food mixers. The three most common constructions of hydraulic motors are the gear, vane and […]

Why do hydraulic valves fail?

By Josh Cosford, Contributing Editor No matter how well engineered or manufactured, no product has infinite reliability, including hydraulic valves. Valves are critical components in hydraulic systems, responsible for controlling the flow, direction, and pressure of the hydraulic fluid circulating to transmit work. When a valve fails, it can cause system downtime, decreased productivity, and […]

How are encoders used in hydraulic actuators?

By Josh Cosford, Contributing Editor Encoders are electronic devices manufactured to relay movement and position. For example, for fluid power applications, the decoder relays an electronic signal to a PLC or other electronic device for the positional measurement of hydraulic cylinders or motors. In most cases, encoders use a light shone through a coded plate […]

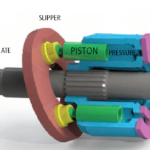

Piston pump technology ensures power and efficiency

By Josh Cosford, Contributing Editor A hydraulic pump is literally the heartbeat of your hydraulic system. If you’re new to hydraulics, you’d be surprised at how many ways you can push fluid under pressure. The rotating and/or reciprocating of gears, vanes or pistons offer a designer constrained by any performance or budget envelope the options […]

Where are compact hydraulic power units used?

By Josh Cosford, Contributing Editor Hydraulic power units are both the source of hydraulic energy and fluid conditioning. The hydraulic reservoir provides a mounting surface for the hydraulic pump and its prime mover while offering up real estate to mount filters, coolers, valves and accessories. In addition, the reservoir stores the hydraulic fluid, providing a […]

Pressure makes it go

By Josh Cosford, Contributing Editor Do me a favor — stand up near a wall just out of arm’s length reach. Now raise your arm with your palm facing the wall and very slowly move toward the wall. Without yet touching the wall, tell me where the force comes from to move your body close […]

Avoid this one piston pump mistake

Hydraulic pumps are primarily designed to convert incoming prime mover energy into hydraulic energy, manifested as pressure and flow. The term hydrostatic refers to a state of pressure equilibrium, especially in a confined space. All traditional hydraulic applications are hydrostatic, and in most cases, if you shut down the pump, physical loads should hold fast […]