By Josh Cosford, Contributing Editor Check valves are the most basic form of directional valve. In their simplest form, a check valve has the singular task of allowing flow in one direction while blocking flow from returning in the opposite direction. These valves are not only simple in their operation but also simple in their […]

Engineering Basics

When should you use cartridge valves?

By Josh Cosford, Contributing Editor Cartridge valves are a type of compact hydraulic valve that slips or screws into the machined cavity of a ported manifold or block. Unlike other valves, such as monoblock lever valves or stackable industrial valves, the manufacturer leaves the porting for you to decide. Cartridge valves still use poppets or […]

How do linear transducers work?

By Josh Coford, Contributing Editor Temperature, pressure, and displacement are typical transducer offerings. A linear displacement transducer measures linear position or distance, especially when high accuracy is needed. Linear transducers work using a principle called magnetostriction. A typical transducer uses three major components; the sensor assembly, a waveguide and a permanent magnet. The sensor assembly […]

What are the differences between proportional and servovalves?

By Josh Cosford, Contributing Editor The line that separates the performance of servo and proportional valves has blurred in recent years. Some may consider a servovalve to be any valve capable of accurately positioning your actuator with closed-loop control. However, in everyday hydraulic circles, many industry professionals describe a servovalve as a valve with a […]

What is the best raw material for hydraulic cylinder repair?

By Josh Cosford, Contributing Editor When your customer’s cylinder arrives on your dock for repair, how often do you consider raw material when you quote the overhaul? Probably very little. Most hydraulic cylinders are manufactured from a combination of 1018/1020 cold rolled steel for the “square” components such as flanges, heads and caps. Piston rods […]

How to specify pressure sensors for hydraulic applications

Learn about common challenges and key specifications to consider when selecting pressure sensors for hydraulic systems with pressures greater than 50 bar (725 psi). Contributed by By Daniel Mullen, Product Manager, Sensata Technologies Pressure sensors are critical components in fluid power systems, where they are used in a control loop with a Program Logic Controller […]

When should you use rotary actuators?

Rotary actuators, in many cases, are a hybrid of linear and rotary actuators. Of course, in the fluid power realm, linear and rotary actuators are more affectionately referred to simply as cylinders and motors, respectively. A cylinder creates linear force when pressure acts up its piston’s surface area, while a motor creates rotational force when […]

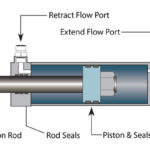

How does hydraulic cylinder repair work?

By Josh Cosford, Contributing Editor When well cared for, hydraulic cylinders should last decades. So long as they were designed for their application — meaning they perform within the bounds of their environment — there should be no reason for damage or wear outside of regular use. The mount, rod and raw material should have […]

What are the most common hydraulic cylinder piston rod problems?

By Josh Cosford, Contributing Editor It would help if you never underestimate the importance of your cylinder rod. The rod is not just the object transmitting the force from the cylinder’s piston but also the interface between that cylinder and your machine. Before you can correctly select and then design the piston rod, you must […]

How do you safely precharge an accumulator?

By Josh Cosford, Contributing Editor When high-pressure hydraulics fail, the result is often a whimper as a seal blows out and pressure decays to useless levels. The harm to the surrounding environment and spectators is often little or none, which is why high-pressure hydraulic systems are so popular. However, when high-pressure pneumatic systems fail, you […]