By Josh Cosford, Contributing Editor Hydraulic valves, used in conjunction with actuators, help make hydraulics unique in its control of force, torque and motion. Valves govern the direction, pressure and flow of hydraulic fluid, enabling smooth, safe control of actuators. A valve’s purpose may be as simple as relieving pressure to protect your pump and […]

Engineering Basics

How do hydraulic brakes work?

Braking systems take advantage of the textbook offerings given by hydraulics — power, controllability and safety. Hydraulic brakes are fairly simple on the cover, requiring a hydraulic pump and a brake actuator. Vehicle braking systems may get by with only what are essentially two cylinders, one at the pump and the other at the brake. […]

What type of flow divider is best for my application?

By Josh Cosford, Contributing Editor Flow dividers provide a unique solution to a specific problem in hydraulic applications — splitting flow while limiting its tendency to take the path of least resistance. Without a flow divider, any time you wish to split flow to two or more downstream subcircuits, the path with the lowest pressure […]

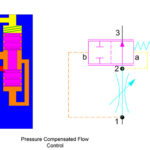

What is pressure compensation in a hydraulic system?

By Josh Cosford, Contributing Editor Pressure compensated pumps, pressure compensated flow controls or even just straight-up pressure compensators – these terms are thrown around constantly. But unless you’re a hydraulic specialist, you may not know what these are, let alone what they do. Of course, you’ve probably heard of systems analysts and cartographers too, but […]

How do hydraulic clutches work?

By Josh Cosford, Contributing Editor A clutch is a mechanical device that disconnects a driveshaft from its input shaft, pausing output torque. Clutches — hydraulic or otherwise — often use friction to engage the input and output ends of the assembly. The friction material is not unlike the compound employed by vehicles for their brake […]

What type of pressure valve do I need?

Pressure valves use a poppet, ball or (rarely) a spool pushed offset by a spring, and that description you’ll find accurate for nearly every pressure valve ever made. This is because a pressure valve simply resists hydraulic pressure until the force to overcome its spring rises above the value of that spring — common sense. […]

How do you select hydraulic pumps?

By Josh Cosford, Contributing Editor Hydraulic pumps convert mechanical energy into hydraulic energy, and it goes without saying every hydraulic system requires such a device to transmit controlled force to the actuators of your hydraulic machine. How you select a pump comes down to many factors but working through this guide will help you select […]

How do directional seated valves operate?

In the most traditional sense, a directional control valve simply dictates the direction of hydraulic flow in some regard. The inline check valve is generally regarded as the most basic version of a directional valve, and simply allows flow in one direction while blocking flow in the opposing direction. Their advantage lies in their simple, […]

When can you use manual hydraulic valves?

By Josh Cosford, Contributing Editor Although many valves have a manual adjustment, as the knob on a flow control or the hex screw on a relief valve, we generally consider a manual valve to be a directional valve operated by a lever, button or knob. Many hydraulic systems run exclusively with manual valves, like your […]

How are ball valves used to ensure hydraulic safety?

By Josh Cosford, Contributing Editor In fluid power, safety is always a concern. Everyone understands the force capacity of hydraulic actuators (which explains why some YouTube hydraulic press channels have millions of subscribers). Indeed, a high-powered hydraulic press can make nearly any material appear no stronger than modelling clay. It’s wise to respect the power […]