Understanding what makes up an HPU is critical in proper design — from pump and style to accumulators and accessories. Read more about HPU design here.

Contributed by Josh Cosford

The reservoir style you choose will be based on price and available space. You should choose the largest reservoir money and space will allow, and if possible, the tank should permit flooded suction. A flooded suction occurs when the pump inlet port is below oil level, either inside or outside the reservoir. L-shaped, T-shaped and elevated reservoirs provide the best combination of attributes, but are large and costly. I’ll describe your primary options, and their advantages and disadvantages.

The JIC Style reservoir is an industry standard welded-top tank that comes with two removable end covers on opposing ends. The removable end covers allow you to access internal plumbing and components for assembly and repair, but also allows for easy cleanout when the reservoir is empty.

Components are typically welded or mounted to the top of JIC reservoirs, such as pump/motor groups, filters, heat exchangers, etc. You can also mount a JIC reservoir on an elevated platform, which provides the below-mounted components with flooded suction and ease of access. Similar to JIC are DIN reservoirs, but with different standard dimensions.

JIC reservoir advantages: industry standard, many sizes available, flexible mounting, cleanout panels

JIC reservoir disadvantages: large size, fixed top plate, requires fabrication

Vertical style reservoirs5 are small and versatile, providing many top mount options with just a few volume options. “Vertical” refers to the vertical mounting of the pump/motor group with a bellhousing dripping down into the reservoir and the motor sticking straight up into the air.

There are many lids which provide various combinations of cutouts for the pump/motor, filler cap and open space for other components to mount to. The vertical mount reservoir is a compact, economical and versatile option available from 5 to 50 gallons or so. Standard components can be bolted on, avoiding the requirement for welding.

Vertical reservoir advantages: compact, economical, versatile, easy to fabricate

Vertical reservoir disadvantages: limited space, difficult to service, limited size/options

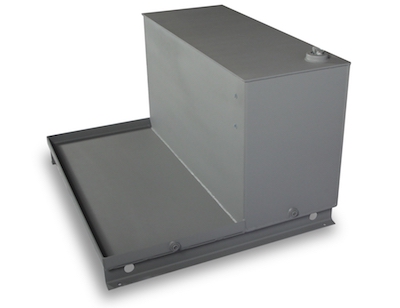

The “L” Shaped reservoirs provide the highest function and serviceability, giving the user flooded suction, space for many components, and a flat bottom for lifting. Pump suction lines are separated with locking ball valves, allowing the pump to be serviced without theatrics.

The pump/motor mounting surface is best included with the deck riser and drain, allowing all spilled oil to be caught and disposed of properly without mess. As well, L-Shaped reservoirs can be had with removable lids, cleanout panels or both. The T-Shaped reservoir is also available for mounting dual, opposed pump/motor groups.

L-shaped reservoir advantages: generous space, ease of service, cleanout panels, many sizes

L-Shaped reservoir disadvantages: cost, footprint