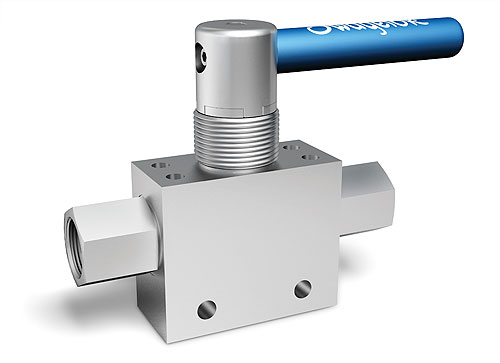

SOLON, OH — Swagelok Company has released a larger size of its popular FKB series medium-pressure ball valve. Designed for improved cycle life in the field, the trunnion-style ball valves provide a leak-tight seal for applications up to 15 000 psig (1034 bar) and feature Swagelok’s patent-pending direct load design, which delivers a more consistent seal across a full range of pressures. Innovative stem and end connection seals prevent shell leakage and provide robust cycle life even in severe conditions.

The two-way 8FKB ball valve complements the original 6FKB ball valve introduced in May 2009. The 8FKB ball valve, with a 0.375 in. (4.5 mm) orifice, offers 1/2 in. gaugeable Swagelok® medium-pressure tube fitting end connections or 1/2 in. female NPT. The 6FKB ball valve is available with 0.209 in. (5.3 mm) orifice and 1/4, 3/8, or 1/2 in. Swagelok medium-pressure tube fitting end connections, or female NPT end connections.

All valves feature 316 stainless steel body construction, and reinforced PEEK seat seals. The valves are rated for temperatures from 0° to 250°F (-17° to 121°C) and maintain a full pressure rating throughout the entire operating temperature range. Multiple O-ring materials are available, including nitrile, fluoroelastomer, and perfluoroelastomer.

Swagelok medium-pressure ball valves deliver reliable and repeatable operation to meet the performance requirements of common off-shore applications, such as topside wellhead control panels, chemical injection panels, well workover panels and control systems. Maintaining the integrity of the valve seal is critical for applications where positive shut off is required. A bottom-loaded stem design eliminates stem blowout for enhanced operator safety.

The FKB series features low-torque actuation, eliminating the need for assist methods and accessories in manual actuation. If pneumatic actuation is required, the valves are available with ISO-5211 compliant actuators. A positionable handle provides flexibility in panel layout by reducing clearance issues with other components.

Swagelok medium-pressure tube fitting end connections provide single turn makeup, or makeup by torque, for reduced installation time and labor costs. Like traditional Swagelok tube fittings, the end connections employ a two ferrule design to deliver robust tube grip, leak-tight gas seal, and vibration resistance.

Designed for the higher working pressures of the oil and gas industry, the Swagelok line of medium pressure products also includes medium pressure fittings and seamless tubing. The all 316 stainless steel fittings are available in a variety of configurations for use with medium pressure stainless steel tubing, both heavy wall annealed and cold-drawn 1/8 hard, and SAF 2507™ super duplex tubing.

Swagelok Company

www.swagelok.com

::Design World::