Each of Muncie Power’s single-acting telescopic cylinders are constructed from a solid, steel piece. With extended stage overlap to minimize bending and reduce hydraulic fluid usage, these cylinders ensure maximum seal performance and reliability.

Each of Muncie Power’s single-acting telescopic cylinders are constructed from a solid, steel piece. With extended stage overlap to minimize bending and reduce hydraulic fluid usage, these cylinders ensure maximum seal performance and reliability.

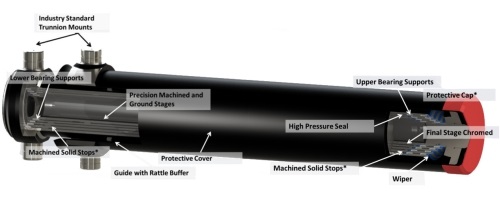

Available in pin-pin and trunnion mounting options, Muncie Power Products single-acting telescopic cylinders are designed to meet various application needs.

Muncie Power’s pin-pin mount cylinders are one of the lightest cylinders on the market and have low maintenance requirements for years of top performance without additional expense. These features translate into greater payloads, less oil consumption and faster dumping.

In addition, the pin-pin mount possesses a self-bleeding design for easier installation, a single head nut with no need for adjustments and a chrome-plated final stage to extend product life.

Muncie Power also offers trunnion mount cylinders, some of the strongest and most stable cylinders on the market. These trunnion mount cylinders allow for increased capacity in the dump body through a significant reduction or elimination of the dog house. Offered in three and four stage versions, the trunnion mount features strict machining tolerances, solid stop contact faces and larger overlap between stages.

For more information regarding Muncie Power’s single-acting telescopic cylinders, please visit www.munciepower.com

For more information regarding Muncie Power’s single-acting telescopic cylinders, please visit www.munciepower.com

Please would you explain the self-bleed feature on your single acting telescopic cylinders? On a tipping tanker application a small amount of air is always introduced into the system when the driver connects the jumper hose to the ram. This connection introduces approx 15ml of air and it appears that there are no features on the ram to bleed it and purge all air. The consequence of this is a massive oil flow from the ram even though the travel has been completed. A technical drawing of the self-bleed feature would be most useful please.