Attendees won’t want to miss four keynote presentations during the Fluid Power Technology Conference at the Milwaukee School of Engineering May 15 and 16. These high-level talks will shed light on trends in the industry and where the fluid power market is headed.

First up is Husco International’s Austin Ramirez, who will open Tuesday with his presentation, “What Washington gets right—and wrong—about manufacturing.” Ramirez, President and CEO of HUSCO, was selected as a White House Fellow and served on the National Economic Council for both the Obama and Trump Administrations. He will discuss HUSCO’s culture and the company’s strategy for success. He will give some general observations on his time in the White House and how he thinks we can fix our political system. Ramirez will explain a policy framework for sustainable success of U.S. manufacturing in an environment of growing populism and a rising China.

Prior to his current role, Ramirez served as President of INCOVA Technologies, a subsidiary of HUSCO, as well as director of strategic business development. He earned an MBA from the Stanford Graduate School of Business as a Goldman Sachs Fellow, and graduated as an Arjay Miller Scholar, awarded to the top 10% of academic performers in the graduating class.

Tuesday will culminate with Eaton Corp.’s Astrid Mozes, VP, Hydraulics Business, Power and Motion Controls’ presentation, “ Dynamic Machine Control: A New Era in Hydraulics.” She will review the Internet of Things’ impact on fluid power. The rise of the IoT in the mobile and industrial markets has delivered intelligent components and automation in ways not previously thought to be possible. What is the next step in IoT integration? Mozes will cover where we are now and what we can expect to come as we enter a new era of revolutionary dynamic machine control that will yield never seen before productivity levels.

Mozes joined Eaton in 1990. She became president – Hydraulics Business EMEA in Dec 2010. Prior to her current role, she was CTO for hydraulics. She holds a bachelor’s and master’s degree in mechanical engineering from The Royal Institute of Technology in Stockholm, Sweden.

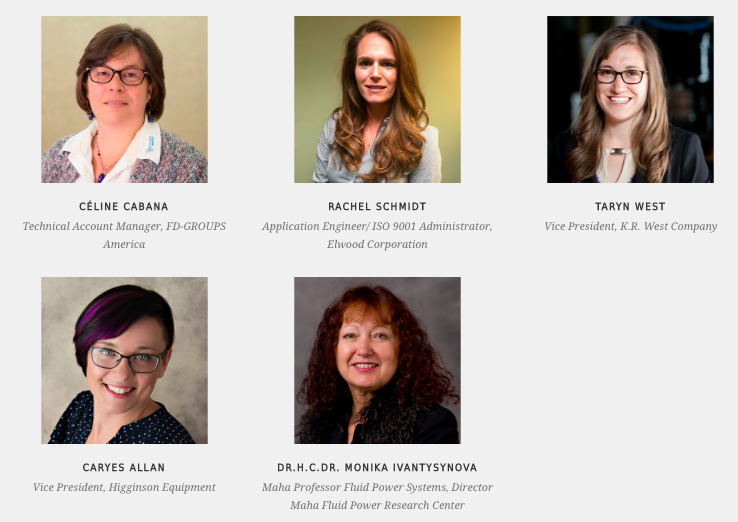

We’ll kick off the day Wednesday with a panel discussion: “Connecting women in fluid power.” Throughout the 2017 edition of the FPTC, one theme resounded over and over again — the need to get more women into engineering and, specifically, into fluid power. Join several leading women from different aspects of fluid power as they discuss why this predominantly male industry has been tough to break into and how we can—and should—make changes to the status quo.

Moderated by me, the panel will include educators, executives, distributors and manufacturers. Panelists scheduled to appear include Dr. H.C. Monika Ivantysynova, Maha Professor Fluid Power Systems and Director of the Maha Fluid Power Research Center at Purdue; Rachel Schmidt, Sales Application Engineer with Elwood Fluid Power; Caryes Allan, Vice President, Higginson Equipment; Taryn West, Vice President, K.R. West Company; and Céline Cabana, Technical Account Manager, FD Groups America.

Finally, the conference will end on an exciting note on Wednesday, with Rethink Robotics’s talk, “Automation for Everyone” as Thomas Munger from Rethink Robotics and Jason Biwer from Price Engineering will highlight how the collaborative robot industry is delivering a disruptive experience to manufacturers across all segments and across small medium and large manufacturers. They will talk a little bit about Rethink Robotics, its company history, and other notable high-level details.

Finally, the conference will end on an exciting note on Wednesday, with Rethink Robotics’s talk, “Automation for Everyone” as Thomas Munger from Rethink Robotics and Jason Biwer from Price Engineering will highlight how the collaborative robot industry is delivering a disruptive experience to manufacturers across all segments and across small medium and large manufacturers. They will talk a little bit about Rethink Robotics, its company history, and other notable high-level details.

Munger and Biwer will discuss how robotics is changing manufacturing and the factory floor—and what lessons fluid power can learn from this fast-moving industry.This exciting session will feature the most innovative breakthroughs in robotics, and an opportunity to meet “Sawyer!”

Sawyer is the revolutionary collaborative robot designed to execute tasks that were impractical to automate with traditional industrial robots. The robot features flexibility, safety and affordability. Sawyer features a 7 degree of freedom robot arm with a 1260 mm reach that maneuvers into tight spaces and operates in work cells designed for humans. Built-in force sensing capabilities allow it to make adaptive decisions as tasks run, enabling Sawyer to work precisely (+/- 0.1 mm), while operating safely next to people.

Attendees can also meet Sawyer and Price Engineering at Price Engineering’s Booth #105.

Visit www.fluidpowertechconference.com for more details and to register.