Overlooking these common causes of hydraulic system contamination could mean catastrophic machine failure. Vigilance is key in maintaining a clean machine. By Carl Dyke. CD Industrial Group Inc. I picture several things when I think of a mobile hydraulic system malfunction: damaged control wiring and connectors a scored valve spool stuck in place a pressure valve […]

Contamination

Large back blow air nozzle for cleaning inside diameters

EXAIRs new 1 NPT Back Blow Air Nozzle has been designed to blow debris and liquids from pipe or hose inside diameters, axle housings, bores, holes, internal threads and other internal part features found in hydraulic cylinders, gear boxes, differential housings and more. An array of holes provide a forceful 360° airflow to clear out […]

How do hydraulic cylinders fail—contamination

Today’s fluid-power users, for the most part, are well aware that keeping hydraulic fluid clean is essential in preventing premature failures and unexpected downtime. Nonetheless, contamination remains a major cause of hydraulic-cylinder failure, particularly because it leads to seal failure and leaks. And it can come from several different and unexpected sources. Internal contamination is […]

What is hydraulic fluid conditioning – part 3

Your oil is wet. No, I didn’t skip 8th grade science class, where you learn how oil and water don’t mix. Okay, so it mixes a bit, if you agitate it enough, but then separates nicely with oil floating atop water. Your hydraulic fluid likes water as much as olive oil likes a bottle of […]

What is hydraulic fluid conditioning – part 1

You’ll have to excuse my shade of indigo. I’m not sure if it’s more Smurf or Na’vi, but back when I first started writing about fluid power, I promised I’d talk about fluid conditioning until I’m blue in the face. I’ll live with the odd skin tone, because fluid conditioning is still one of […]

OPCount particle counter for mobile and stationary equipment

The latest generation of OPCount particle counters from Argo-Hytos can be used for stationary and mobile operation. The high measuring accuracy of the OPCount, in connection with the possibility to display the measured particle concentration according to all current standards, allows it to be used in a variety of applications. Measurement can be carried out […]

Reliable Plant exhibition focuses on industrial fluid systems

Clean, dry hydraulic fluid is the lifeblood of any hydraulic system. And keeping all gear oils, lubricants and other fluids within an industrial system contaminant-free is critical to efficient and reliable machinery. That’s why there is an entire trade show and technical conference dedicated to these technologies each year, called Reliable Plant, sponsored by Noria […]

Why the ISO code matters

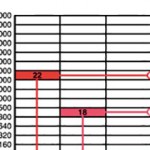

Earlier this month, I explained the meaning behind the ISO 4406 contamination code, so now I’m explaining why it matters, and how you can apply it to your application. The code describes the quantity of 4-, 6- and 14 -μm particles in a milliliter of hydraulic fluid—because these particle sizes are considered the most damaging […]

Understanding ISO 4406

The most critical quality of hydraulic fluid you should consider is that of cleanliness. We refer to the size and quantity of particle contamination when discussing cleanliness, and so that we are all on the same page, standards were created for measuring and expressing this quality. Although the standard for oil cleanliness has changed over […]

Hydraulic fluid contamination: The greatest danger to your system

David Marlowe • Owner/CEO • DMAR Technical Training and DMAR Business Centers When conducting a class on hydraulic and lube oil systems, I often find that the students are surprised by how much fluid condition affects system operation and the numerous mechanical problems that derive from the oils not performing at 100% of design characteristics. […]