If you’re not familiar with the basics of hydraulic filtration, just wait a week. A week is all it takes to be bombarded by blogs, articles and advertising on the importance of hydraulic filtration—and rightfully so, as it’s the most critical consideration you can make if you’re serious about reliability. I’m guilty of lecturing readers and customers alike on the gravity of maintaining clean, dry and cool hydraulic fluid.

However, one of the less discussed aspects of filtration is the media chosen for a given application. I have written about filtration efficiency enough to give even a seasoned writer blisters on his or her fingers, but how many of you really know what a filter is made from? There are a few primary choices and I’m happy to provide the inside scoop on them.

Paper is used in more places than mâché and fax machines. Cellulose paper is made from wood pulp, and the paper used to create sheet material for hydraulic filters isn’t much more sophisticated than the paper you scribble notes on. The upside is that it’s cheap, and it can be recycled from post-consumer waste. The downsides are that it’s neither very efficient nor does it have very high dirt holding capacity. One aspect, which can be a benefit or hindrance, is its tendency to absorb water. They can be used to remove water from hydraulic oil, but if that’s not a desired effect, it will still absorb water and increase pressure drop, making it seem as though the filter is clogged.

“Paper” filter elements can also be made from polyester, which look similar to their cellulose counterparts. Realize polyester filters aren’t the most efficient material to filter with, but they’re inexpensive and aren’t very hygroscopic, meaning they don’t absorb water. This allows you to use a cheap filter in applications where water removal isn’t necessary.

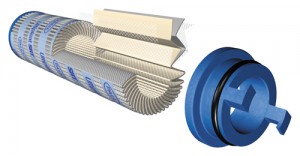

Synthetic filter media are the current gold standard for quality of filtration. They are manufactured from synthetic glass fibers, which are very fine and consistent in texture. Multiple layers of differing quality are used to create a medium that is both extremely efficient and offers great dirt holding capacity. The problem with fine filtration is that the particles can clog the orifices, but the depth-type media of synthetic filters allows huge dirt retention, especially compared with other surface-type media.

One such surface-type medium is with mesh metal screens. It is constructed of either standard or stainless steel in a woven mesh. Because of the limitations in wire size and construction techniques, they are not available in very fine micron ratings. However, they have an advantage of being the only common type of filter element you can clean and then reuse. One could debate the reuse of a filter is a good thing, because the process of cleaning the element can put particles on the wrong side of your filter, allowing them to circulate through the system on start up.

The filter medium matters less than your contamination control plan, as each choice has its benefits and detriments. The appropriate choice depends on your application, and as long as you have an intelligent system for controlling contamination, each media will have its place in the vast range of machines in existence.