Sun Hydraulics Corp. has announced the availability of 16 completely new solenoid-operated cartridge valves and three new coils for the mobile and industrial hydraulics marketplace.

Sun Hydraulics Corp. has announced the availability of 16 completely new solenoid-operated cartridge valves and three new coils for the mobile and industrial hydraulics marketplace.

These newly designed valves—including on/off and proportional models—are the first phase of products introduced in the Sun FLeX Series Solenoid Valves. Coil options for the family include interchangeable low-power, high-power and hazardous location (explosion-proof) versions for expanded configuration flexibility.

Designed to outperform comparable valves on the market, the FLeX Series solenoid valves offer consistently better pressure drop in a virtually leak-proof poppet-style valve that is designed and tested to exceed 10-million-cycle operations. All the valves and coils in the FLeX Series are zinc-nickel coated to offer 1,000-hour salt fog protection, so they’re suitable for a wide range of demanding applications. They incorporate the unique Sun floating-style construction to minimize the possibility of internal parts binding due to excessive torque and/or machining variations. And with their competitive pricing, the Sun FLeX products deliver excellent value for the money.

This expanding family of performance-driven solenoid valves complement Sun’s existing line of electro-hydraulic valves and their industry-leading line of load-holding, pressure-control, flow-control, directional, logic and multi-function mechanical-operated valves. As with all Sun’s valves, the new FLeX Series products will be available in Sun’s QuickDesign online integrated package design program, allowing users to create and order custom packages incorporating these new products.

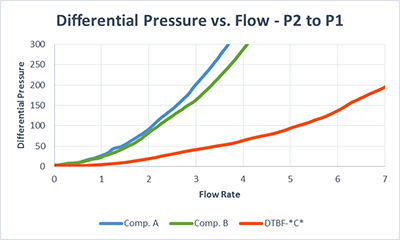

As an example of FLeX performance advantages, the DTBF normally closed, direct-acting blocking poppet valve has been designed and tested to provide superior performance. Ad-vanced computational fluid dynamics (CFD) simulation tools were used to optimize flow path geometries. Additionally, the solenoid actuator has been designed to provide the ide-al actuation force at critical points in the valve’s stroke. These tools provide two big advantages:

• Lower pressure differential across the valve at a given flow rate

• Increased shift performance at higher pressures and flows

This means that hydraulic systems that use the DTBF will see improvements in efficiency and reliability while still allowing for performance at high pressures and flow rates. Below are curves comparing the new FLeX Series valves to comparable valves from industry competitors.

All FLeX valve designs were optimized with CFD fluid simulation to improve pressure drop performance. In addition, all FLeX valves meet the new NFPA test standard t1.6.1 R2014 for fatigue and burst pressure ratings.

Initial FLeX Series offerings include the following products:

Four Two-Way, Direct-Acting, Solenoid-Operated Directional Blocking Poppet Valves Available In Normally Open And Normally Closed Models

• DTAF pilot-capacity models leverage Sun’s T-8A cavity design and can be used to pilot larger, higher-capacity valves

• DTBF valves use the Sun T-162A cavity.

• Both models can use any of the three coil types (low-power, high-power and explosion-proof) in the normally closed version

• Neither requires hydraulic pressure for operation.

Eight Two-Way, Two-Stage Solenoid-Operated Directional Blocking Poppet Valves

• DFB* family of 10-gpm (40-L/min) valves offer either 3,000-psi (210-bar) or 5,000-psi (350-bar) maximum operating pressure with improved pressure drop and reliable op-eration across their full operating range.

• 3,000-psi (210-bar) valves (DFBD and DFBE) use the low-power coil

• 5,000-psi (350-bar) valves (DFBF and DFBG) use the high-power coil

• All FLeX valves can use the explosion-proof coils.

Four Pilot-Operated Electro-Proportional Throttle Valves (Two Normally Closed & Two Normally Open)

• Excellent command-versus-flow and pressure differential-versus-flow performance.

• Compatible with Sun’s new compact, powerful XMD driver to deliver finely tuned control for demanding hydraulics applications.

• 5,000-psi valves use either the FLeX high-power coil or the hazardous location coil as needed.

Low- and High-Power Coils In Six Voltages, Two Connector Options

• 740 Series Low- and High-Power Coils available in 12, 14, 24 and 28 Vdc and 115 and 230 Vac.

• DIN 43650 Form A (IP65/IP67 rated) and Deutsch DT04-2P (IP69 rated) connectors.

• The low-power coil draws 17 W, and the high-power coil draws 25 W (at 20° C).

• Transient voltage suppression (TVS) diode is optional for dc coils and standard for ac coils.

Hazardous Location (Explosion-Proof) Coils In Four Voltages, Two Connector Options

• 747 Series Hazardous Location Coils include ATEX, IECEx and CSA global certifications

• Are compatible with all the FLeX Series valves.

• Certified for gas and dust environments (T4 compliant for gas and T135° C for dust) and are CE compliant.

• 30-W coils and come in 12- and 24-Vdc and 115- and 230-Vac.

• DC coils have an integral TVS diode offering a 48-Vdc breakdown voltage

• AC coils are internally rectified.

• 90° and 180° connector options with either 1/2-in. NPT or M20 x 1.5 female thread for electrical connections.

Sun’s new FLeX Series solenoid valves and coils are available for order immediately through the global Sun Hydraulics Authorized Distributor network and will begin shipping in January, 2018.

Sun Hydraulics

www.sunhydraulics.com