The big highlight for Bosch Rexroth at this year’s MinExpo held in September was its new Hägglunds Atom hydraulic motor. Smaller than traditionally offered over the years, the Atom was actually developed several years ago under a different name but at a much lower pressure rating, said Brian Howell, Hägglunds Sales Manager. But the market feedback showed that while users liked the motor, they would use it more if it had higher pressure ratings.

“So the R&D team went back to work. They made some design changes and we ended up with this Atom Motor, which is our 5,000 psi rated new hydraulic motor but in a much smaller package size. Essentially what we have is a motor that basically is a very power dense solution for the market,” Howell said.

Weighing about 100 lb, the Atom motor can output about 400 hp up to about 400 rpm, providing a lot of power in a very small package size. “This really opens up some new opportunities for us, especially with customers that have space constraints in their machines. They’re looking to reduce weight in their machines,” Howell said.

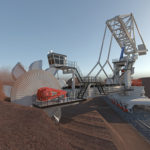

The Atom is suited especially for mobile processing machines in the mining industry, whether it’s for aggregate or for heavy mining applications like copper mining or gold mining. Specific applications include conveyors and smaller crushers on mobile drill rigs, apron feeders, and crushers and sizers.

All Hägglunds motors, including the Atom, offer very high overall efficiency, generally more than 95%. “We’re very efficient at transmitting power to a driven shaft. And again, weight and space savings are critical topics that many of the OEMs that are building machines today face every day with their customers because everybody wants an overall smaller package size of a machine,” Howell said. “They need it to be lighter in weight because they’re trying to get into new areas and explore where maybe they haven’t been before. So those are all really critical elements that we hear very often from many of our customers — that reducing weight and reducing the space needed to have a drive solution is super important.”

Visitors to Rexroth’s MinExpo booth could see the Atom with a clear cover connected to one of Bosch Rexroth’s drives. Additionally, a control system and touch screen display were also included to highlight the company’s condition-based monitoring for systems it provides as well as the machinery that said system is driving.

With continuous data collection, the user can analyze data and determine how a machine has performed over the last day, the last week, or the last month. It shows them trends of performance. They can see trends on things such as system temperature, system pressure, and system speed. If there are other sensors in the process that the user would like to monitor and trend as part of the application, Rexroth can even bring those sensors in and monitor those as well.

“It gives the customer a little higher level of visibility to how their machine is performing in their process and allows them to almost real time see, ‘Did we have an event happen that we need to somehow mitigate by sending maintenance people out to the machine,’” Howell said. “We’re really pushing this on the market. We had a lot of interest in this condition-based monitoring and being able to monitor the health and the index of your system is a really a key trend in the industry right now.”

Two versions of this solution are the CM or CMP versions. The CM version is a condition monitoring system that collects the data, monitors it, and then the customer can analyze it on their own. The CMP allows Bosch Rexroth to real time analyze the customer’s data for them and give them frequent reporting back on how their system is performing.

“Sometimes customers will be surprised when our service techs tell them, ‘This drive has been in service now for 10,000 hours or 15,000 hours,’ and the customers are really surprised about that. They’ll be like, ‘Wow, we didn’t realize we had that much usage of this machine,” and then it helps them to plan their maintenance activities a little better, and how many times a year do they need to do maintenance on their equipment and their machines,” Howell said. “It does provide a much higher level of visibility which a lot of these customers need today.”

Bosch Rexroth

www.boschrexroth.com