The recent Intermat exposition in Paris was Europe’s largest construction-equipment show slated for 2018. One of the highlights, the Intermat Innovation Awards, showcased some distinguished products and equipment for the construction and materials industry. Among the entries, here are some notable fluid-power related designs.

Construction vacuum lifter

AL-Blazer 2000 from AL-Lift is a vacuum lifting attachment for fork-based vehicles like loaders and trucks, or for use on the 3-point-hitch on tractors. It can lift products weighing up to 200 kg, thanks to a powerful 90 cubic meter/hr vacuum pump, powered hydraulically by the vehicle engine. The high-capacity vacuum pump ensures that even porous tiles with an open cell structure can be lifted.

A quick-coupler system lets users change suction plates in minutes, and a wide assortment of plates for various sizes and weights are available. The device helps enhance worker safety and considerably reduce handling time, compared to manual labor. The two-joint-arm covers a 6-m diameter over a 280° work area. Lifting height is 1.1 m from ground to suction pad and overall height is 2.5 m, so there is no need for folding during transport.

Motorized wheelbarrow

The mechanized Cepia wheelbarrow from Fayat aids workers spreading hot-mix asphalt (HMA) and aggregates. The concept is simple—a small engine powers a hydrostatic drive. No special operator training or electronic controls are necessary, and the unit has only three control options: opening a chute, propelling forward and backward, and adjusting height.

Individual gates adjust spreading width, and hydraulic jacks on each side can level the machine for work on banked surfaces. Tipper capacity is 150 liters (2.5 times more than a standard wheelbarrow) and aggregates spreading speed is to 4 km/hr. Exhaust gas heat recovery from the engine heats the spreader and makes it easier to apply HMA. It reportedly handles as easily as a classic wheelbarrow for accurate work, even on sites with restricted space. But the self-propelled machine helps protect workers against muscular-skeletal disorders.

Connect energy link

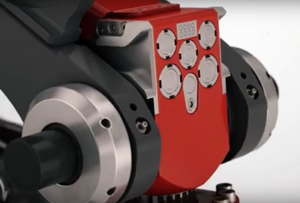

Mecalac’s Connect Energy Link is said to be the safest quick-coupler for excavators with hydraulic and electric connections for tools and attachments. The compact design builds on the Mecalac Connect quick-coupler launched in 2015. In this new Energy Link version, a coupling interface mates the machine and attachments without operator intervention. The coupling system simultaneously connects five hydraulic lines (two return lines and a drain return line) and an 8-pole electrical connector.

On the accessory side, the coupling interface is fixed on a moving cam equipped with centerers. Approaching the accessory progressively guides the centerers in position to ensure hydraulic and electrical coupling. The system has redundant security features. An RFID sensor detects and identifies the accessory; a second sensor detects the perfect mechanical locking of the quick-coupler. The advantage is that hydraulic lines only pressurize when the RFID chip detects the presence of a tool, identifies it, and confirms the mechanical lock. The RFID chip also automatically adapts the flow rate and hydraulic pressure according to the characteristics of the tool.

The design ensures the depressurization of the hydraulic lines during coupling and decoupling. In addition, the couplers have a double sealing chamber to minimize oils leaks. The hydraulic and electrical coupling does not slow down the usual attachment procedure, as it enables a hydraulic tool change in just a few seconds.

Cylinder inside boom

Doosan Bobcat engineers look to maximize the protection of boom cylinders and address one of the weakest points on 2.5-ton mini excavators. The new design fully covers the hydraulic cylinder with an extended boom structure, to avoid possible collisions with the top of the blade.

The boom structure protects the hydraulic boom cylinder regardless of position or movement. It improves robustness and durability and significantly reduces the cost of service, spare parts and downtime. And in environmental terms, better protection prevents cylinder damage and risk of ground contamination by leaking oil. The added protection is particularly suitable for machines with less-experienced operators—such as typical in the rental market.

Hydraulic crusher bucket

The Triple R System from MB Crusher simplifies the traditional means of crushing, screening and recycling material on excavation and demolition sites. According to the company, it is especially suited for built-up and residential areas that have restrictions on dust and noise, and which can’t be accessed with large machinery.

The Triple R System consists of an MB crusher bucket with attached iron-separator and dust-suppression kits. The bucket is powered by the machine hydraulics; the largest unit requires around 60 gpm flow at about 3,100 psi. The bucket picks up the material and its jaws break it into smaller pieces. The separator collects ferrous material from the crushed materials, while the dust suppression kit reduces airborne dirt and particulates. The unit crushes waste materials on-site for repurposing, recycling or disposal. It is suitable for various machines, including excavators sized from 4 to over 70 tons.

New range of hydraulic motors

To address OEM demands for higher performance and efficiency from hydrostatic transmissions, Poclain Hydraulics offers an extended range of high-performance motors available in five sizes, MHP11 to MHP27, with displacements from 55 to 214 cu. in. per revolution. According to company officials, the MHP range offers groundbreaking power levels in a compact design which, for machine builders, leaves additional space for the engine and other components and makes assembly easier. The MHP27, for example, runs as speeds to 340 rpm, generates maximum torque of 17,700 ft-lb and is rated at 375 hp. Maximum pressure is 7,252 psi.

The MHP also generates lower losses compared to traditional hydraulic motors. The cam-lobe design offers efficiencies over 90%, even at the highest speeds. The products with a closed cover and high sealing protection have been engineered to withstand dirt, water, shock loads and other severe operating conditions. The units are suited for machines requiring robust, high-performance and fuel-efficient systems, such as ag equipment and drilling rigs.

Stabilization-cylinder sensor

The MRT 2470 and MRT 3050 rotating telehandlers from Manitou use a strain gage inside the pin of stabilizer cylinders to track information on the exerted force on the ground. This system increases machine and operator safety. In use, machine lifting action creates stresses on the pin that micrometer strain gages measure and send that information to the machine controller, which interprets the data to determine the working positions and loads on each stabilizer.

While automatic stabilizer recognition and monitoring has been used on telehandlers, the new system reportedly permits higher precision and safety, and reduces of number of components for simpler assembly. It also improves safety on the job site because the gage measures ground pressure continuously, important should load values change.

Hydraulic vibrating system

Dynaset’s Hydraulic Vibrating System (HVB) brings vibrating capability to a standard hydraulic cylinder. Adding the HVB to the cylinder’s hydraulic circuit creates a frequency and displacement controlled pulsation, which drives the cylinder shaft into vibrating the equipment it moves. It reportedly adds new functions to existing machines, which improves performance and productivity.

The HVB converts the hydraulic power of a mobile machine into vibration power. When activated, the HVB initiates rapid back-and-forth movement of the cylinder, creating vibration to the attachment. It is an effective tool to enhance frozen ground penetration, pile driving, bucket emptying, asphalt cutting and soil compacting. And the HVB is reliable and safe for the base machine, according to Dynaset, as it creates less stress to the boom than a hydraulic hammer or rock breaker.

For example, an excavator with an HVB-equipped cylinder lets the bucket: act as vibrating ground pre-compactor, set poles effortlessly, enhance penetration capacity in hard ground, and empty/clean itself from sticky materials more efficiently. The unit is push-button actuated on demand from the cab. Three different models run at frequencies from 19 to 30 Hz. Flow requirements are 10 to 21 gpm, depending on the size, with maximum operating pressure of 5,076 psi.