At MinExpo last fall, Parker Hannifin’s Hydraulic Pump and Power Systems Division released a complete electrification system spotlighting its new GVM310 global vehicle motor and P1M series mobile open-circuit, medium-pressure axial-piston pump.

The GVM310 is a powerful, rugged, electric vehicle motor for both heavy on and off-road vehicles, engineered for traction and electrohydraulic pumps (EHP) up to 409 kW peak power. With a ten-year legacy and thousands of units sold, the high-power density and speed capabilities of Parker GVM motors combined with a voltage matched inverter provide the speed and torque required to achieve breakthrough performance, superior efficiency, in a variety of hybrid and electric vehicle platforms.

It is rated for power up to 228 kW (continuous) and peak torque up to 1430 Nm. A variety of available magnetic options allow for a wide range of voltage, speed, and torque requirements. The GVM family achieves high power density thanks to a patented liquid cooling system, which also results in a cleaner, less complex, oil-free design. The GVM310 is an example of how Parker is providing the building blocks for vehicle electrification, developing turnkey technologies that cut time to market while reducing supply chain complexity.

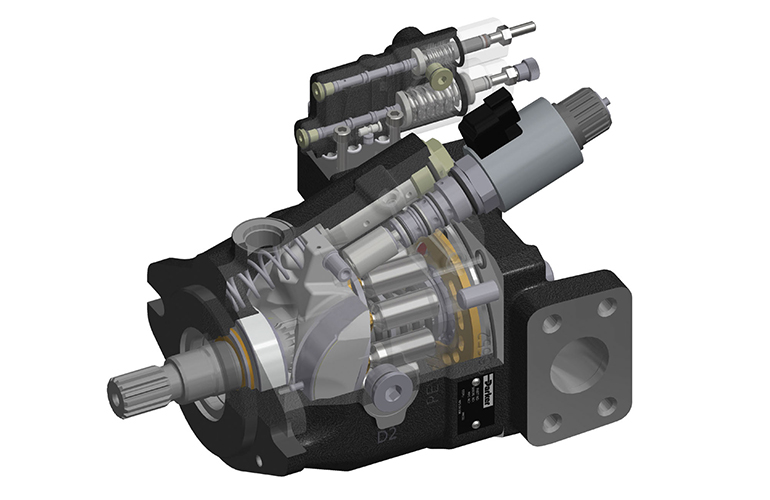

Parker’s P1M series axial piston pump delivers high speed and efficiency, reduces costs, and extends pump life in a robust, compact envelope. It features a patented inlet and optimized port plate design, which increases speeds and improves durability, standard dual shaft seals for wet PTO mounting, and extensive, modular control options, which enable complete circuit customization. Its nine-piston design also reduces pressure ripples.

A patented inlet design on the P1M increases speed ratings and fill capabilities while reducing erosion, cavitation, and pressure ripples. Because it features a compact package, it fits into tighter spaces and offers best-in-class power density due to higher pressure ratings, speeds, and efficiency. Optional dual shaft seals are available for wet PTO mounting for all sizes.

The pump and motor work together to create an efficient electrification system for a wide variety of applications ranging from mobile construction equipment to large mining trucks.

“With the recent merger of Parker’s EMD’s electric motors and gearboxes, Parker HPS is focused on the future of both electric and hydraulics solutions. By combining electric motor technology and hydraulic pumps, HPS is confident we can deliver highly integrated and versatile electro-hydraulic functions for a wide variety of applications,” said Keith McDonald, product manager, Hydraulic Pump and Power Systems Division.

Parker Hannifin

parker.com