Argo-Hytos’s screw-in cartridge program offers a wide function range for mobile and industrial hydraulics for control of flow direction and pressure in a hydraulic circuit. The most common applications include agricultural machines, construction equipment, municipal vehicles, machine tools and wind power plants etc.

Argo-Hytos’s screw-in cartridge program offers a wide function range for mobile and industrial hydraulics for control of flow direction and pressure in a hydraulic circuit. The most common applications include agricultural machines, construction equipment, municipal vehicles, machine tools and wind power plants etc.

Hydraulics users are looking for reliability, increased operating comfort, and reduced TCO (Total Cost of Ownership). Along these lines, Argo-Hytos new cartridge valves have an extended life that can be attributed to a surface protection 520 h according to ISO 9224 as standard. The robust design and its seals withstands a 10 million cycle lifetime test. In addition, as part of the company’s offerings, oil resistance to high oil/ambient temperature is standard.

Screw-in cartridge spool version

Screw-in cartridge spool version

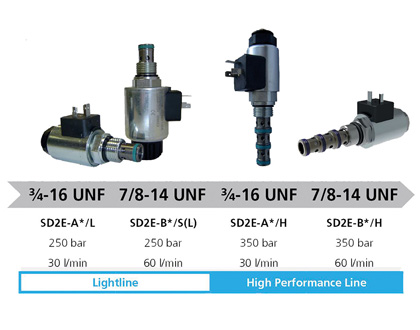

These valves are designed to control flow direction. The connection sizes are executed by two different threads—3/4-16 UNF and 7/8-14 UNF. Operating pressure is up to 350 bar. The flow rate is limited up to 60 lpm for connection size 7/8-14 UNF and 30 lpm for connection size 3/4-16 UNF. Two performance product families are available—the “High Performance“ version is designed for valves up to 350 bar, while the “Lightline” version is up to 250 bar.

Screw-in cartridge poppet version

A poppet version is available up to 75 lpm and 420 bar which is applicable for all ports. Precision machined parts secure a leak-free closing up to 3 drops/min.

A complex production program range includes different possibilities such as normally open and normally closed versions, pilot operated or solenoid operated variants, and a wide range of solenoids and connectors. The standard surface treatment of the valve and solenoid is a ZnCr3 coating to secure 240 h in salt spray according to DIN 9227, however, a surface treatment up to 520 h is possible. They offer a favorable ratio pressure drop/transmitted hydraulic power/leakage. Finally, the functionality in case of system malfunction is boosted by different manual overrides.

A complex production program range includes different possibilities such as normally open and normally closed versions, pilot operated or solenoid operated variants, and a wide range of solenoids and connectors. The standard surface treatment of the valve and solenoid is a ZnCr3 coating to secure 240 h in salt spray according to DIN 9227, however, a surface treatment up to 520 h is possible. They offer a favorable ratio pressure drop/transmitted hydraulic power/leakage. Finally, the functionality in case of system malfunction is boosted by different manual overrides.

The poppet version of the directional valves SIC offer the following advantages and features:

- Excellent price/quality ratio

- Low pressure drop

- Leakage free

- High hydraulic transmitted power

Electrically switchable SR4E-B2/H pressure relief valve which is a solenoid-operated, spool type, piloted version offers the following features:

- Designed for cost-efficient and compact installation, typically used for motor control circuits

- Combines the functionality of a normally-open solenoid valve with a pressure relief valve

- Two-stage pressure valve for ON/OFF function

- Excellent stability throughout the entire flow range with rapid response to dynamic pressure changes

- Pump unloading

- Operating pressure 350 bar

- Rated flow = 60 lpm

- Low hysteresis, accurate pressure control and low pressure drop through CFD optimized flow paths

- Coils interchangeable

The SR4E-B2/H multitasking pressure relief valve is provides comfort functionality while simultaneously offering space and price reduction.

The SR4E-B2/H multitasking pressure relief valve is provides comfort functionality while simultaneously offering space and price reduction.

This 7/8-14 UNF valve is used as an integrated two-stage pressure valve for unloading the flow passage. It supports the setting of two pressure values, pmin and pmax. While energized, the valve blocks the low-pressure passage and allows the pressure to rise up to the adjusted value of the relief pressure. Both pmin and pmax are manually adjustable.

Screw-in spool valves feature a “tumbling nose” to compensate the cartridge misalignments in the cavity. They provide compensation of too high torques during assembly. This feature always secures the right valve position in the cavity, therefore the spool never gets blocked.

Screw-in spool valves feature a “tumbling nose” to compensate the cartridge misalignments in the cavity. They provide compensation of too high torques during assembly. This feature always secures the right valve position in the cavity, therefore the spool never gets blocked.

In connection with a precision CNC machining of the cartridge housing, a low leakage performance is reached, which is similar to the performance of the poppet valves available on the market.

The housing machining is done on a CNC turning machine with SPC (Statistical Process Control), then the hardened housing is machined on a CNC centerless grinding machine and honed. Both machining processes, grinding and honing, are supported by automatic feedback.

Polyurethane sealing on the cartridge allows easy assembly through a high resistance to twisting and a long life time.

Argo-Hytos

argo-hytos.com