Most users of fluid power technology know that water in a hydraulic system can wreak havoc to the system and components, resulting in possible failure. This is why Wix Filters, a global manufacturer of filtration products, has launched what it calls the world’s first proactive molecular hydraulic oil water absorber.

Most users of fluid power technology know that water in a hydraulic system can wreak havoc to the system and components, resulting in possible failure. This is why Wix Filters, a global manufacturer of filtration products, has launched what it calls the world’s first proactive molecular hydraulic oil water absorber.

The hydraulic oil water absorber offers ongoing protection by removing all forms of water—bound, free and emulsified—in all hydraulic oils. The new product also:

- Neutralizes acids that cause metal surface corrosion and rust

- Absorbs peroxides which lead to oxidation of oil and degradation of rubber components

- Stops hydrogen embrittlement (metal pitting) and oil viscosity variance issues

- Stops hydrolysis in synthetic esters as well as bacteria and algae contamination

“It goes without saying that water is the enemy of fuel and oil systems,” said Donald Chilton, vice president of product management for WIX Filters. “The complications water causes can lead to significant setbacks for our customers and their businesses. We set out to create something that would prevent the water problem before it starts, and this product does just that.”

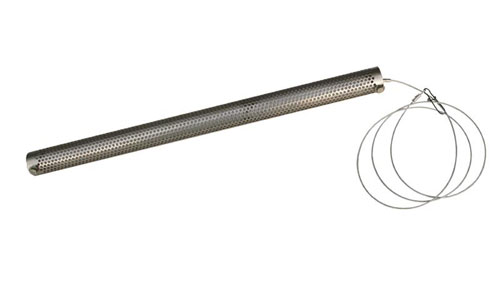

To use, simply attach the tether clip to the inside of the filler cap for retrieval. There should be free and clear access through the tank opening of 1.25 in. or greater before inserting the unit into the tank. Once the water absorber exceeds 300 ppm, remove the tether clip from the tank filler cap, remove the tube from the tank and repeat the installation steps.

The absorber is available to treat 20-, 40- and 60-gal tank sizes. In terms of a replacement schedule, if there is heavy equipment use and/or high humidity, the water absorber should be replaced every 30 days. If the equipment is used more intermittently, or every 120 days, and if the water absorber is simply being stored, it should be replaced annually.

“These are approximate recommendations and will vary based on the equipment and its use,” Chilton said.

Wix Filters

www.wixfilters.com