Any OEM producing mobile machinery for industries such as construction, mining, agriculture or energy, will be familiar with the limitation of having to design hydraulic solutions around standard parts. Most hydraulic valve manufacturers, for example, will typically seek volumes of around 5,000 to 10,000 a year to design a new valve. As a result, many OEMs make do with standard issue, and have to design their systems accordingly. But it doesn’t have to be that way anymore.

Any OEM producing mobile machinery for industries such as construction, mining, agriculture or energy, will be familiar with the limitation of having to design hydraulic solutions around standard parts. Most hydraulic valve manufacturers, for example, will typically seek volumes of around 5,000 to 10,000 a year to design a new valve. As a result, many OEMs make do with standard issue, and have to design their systems accordingly. But it doesn’t have to be that way anymore.

Webtec has introduced a custom hydraulic solutions service based on much lower volumes of typically 100 to 5,000 pieces per year, depending on cost and complexity. This provides major benefits for design engineers at OEMs, who instead of resigning themselves to using a standard product, now have access to a myriad of bespoke solutions. The advantages of taking the custom route include greater design freedom, as well as enhanced form, fit and function of components, not to mention elevated performance and greater compatibility.

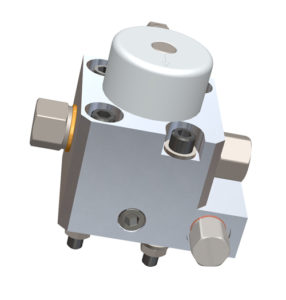

Based on a service that comprises research, development, test and manufacturing, the custom hydraulic solutions offered by Webtec can include many different components. For instance, special combination monoblock valves for flow, pressure and directional control can be designed that help to reduce the size of the system envelope and piping, and cut assembly costs. Alternatively, any OEMs looking to reduce energy consumption and prevent overheating will benefit from Webtec’s ability to produce custom-designed, high-efficiency flow control valves to suit exact requirements. The company can also manufacture real-time systems for monitoring parameters such as flow, pressure, temperature and contamination, thus helping to reduce downtime or warranty claims.

In essence, Webtec’s custom hydraulic solutions are designed in line with specific specifications, ensuring customer machines have that all-important edge over the competition.