By David Marlowe • Owner/CEO • DMAR Technical Training and DMAR Business Centers USA

Petroleum-based hydraulic fluid has a variety of desirable characteristics, including lubricating and anti-wear properties, so it is often the preferred fluid for hydraulic systems. For these uses, petroleum oil is highly refined to remove undesirable chemicals while other chemicals, such as additives, are added to improve the oil’s performance. One of these other chemicals is a viscosity index improver.

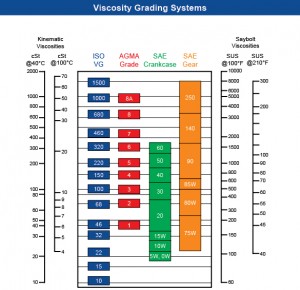

Viscosity index should not be confused with viscosity; it is an altogether different kind of rating. Viscosity rating is a measure of the oil’s resistance to flow or thickness, and is the single most important characteristic of hydraulic oil. The viscosity index number indicates the extent of thickness, or resistance to flow, with temperature changes.

Viscosity—Because an oil’s viscosity changes with temperature, it is always expressed at a reference temperature, usually 100° and 210° F. The most common unit in the United States is the Sabolt Universal Seconds (SUS) or Sabolt Seconds Universal (SSU), which is measured with a Saybolt Viscosimeter. The tested oil is brought to 100° F and poured through a standard orifice of 0.0695 in. in diameter. The time measured in seconds for a volume of 65 ml to flow through the orifice is the rating of the oil. Lower viscosity fluids will flow more easily and faster, while high viscosity fluids will flow more slowly. If the tested oil takes more than 1,000 sec for the 65 ml to flow, the tested oil temperature is increased. As an example: 30W oil flows much faster at higher temperatures.

The pump and hydraulic motor are most sensitive to viscosity, so you must be sure to only use suitable oil according to the manufacturer specifications. Other system components are less sensitive to viscosity. If the oil is too thin (low viscosity) not only is it hard to pump, but slippage will accrue due to leakage past clearance spaces, between gears, vanes, piston seals and valve spools, thus effecting overall system efficiency. In most systems the normal viscosity range is from 100 to 750 SUS/SSU.

Viscosity also increases with pressure. For example, at atmospheric pressure the oil can increase from 150 to 750 SUS/SSU at an applied pressure of 10,000 psi, with the temperature in both oils remaining the same.

Viscosity Index (V.I.)—Viscosity index numbers are devised on a scale of 0 to 100, which indicates the extent of viscosity change. Thus 0 indicates an oil with the greatest change over a certain temperature while 100 indicates an oil with the least change over a certain temperature. All other oils fall within these extremes. With the addition of chemical additives, the V.I. rating has been extended considerably above 100. The most desirable hydraulic oils have the least amount of viscosity change and a V.I. rating of 95 or higher. V.I. ratings are not units of measurement; they are relative terms for comparing variation in viscosity of one oil to another. ISO viscosity grades are often the most commonly used when describing a hydraulic fluid’s properties.

Finally, temperature can have a major effect on hydraulic oil. Keeping oil to a moderate temperature level is an important requirement for reliable operation. Oil life is cut in half for every increase of 20° F in temperature. Oil life at 210° F is only 1⁄16 of that at 130° F. High temperatures can also cause chemical reactions, such as oxidation, and reactions with minute quantities of acids present, also shorten oil life.

In addition, in a cold environment, the hydraulic unit should operate at a temperature at 60° above surrounding atmospheric temperature. The oil’s viscosity and V.I are critical for low temperature operation. It is important to monitor start-up and operating temperatures, allowing enough time for the machine to warm up before putting it into high speed or heavy operation.

please what are the examples of viscosity index