Manufacturers of mobile machines must decide whether to control their pumps using pressure, torque or swivel angle — and always have to accept compromises as a result. The same applies to numerous other hardware parameters which, once defined, stay the same throughout a machine’s service life.

According to Simon Dreher, an excavator industry specialist with the Mobile Hydraulics Group at Bosch Rexroth, Lohr am Main, Germany, today’s hydraulic systems mainly rely on pure hydro-mechanically controlled components like pumps, joysticks or valves. “We all know that for every single machine, this takes installation and hardware effort in combination with poor flexibility because once the machine’s behavior has initially been set, it can usually not be changed, or only with manual effort,” he said.

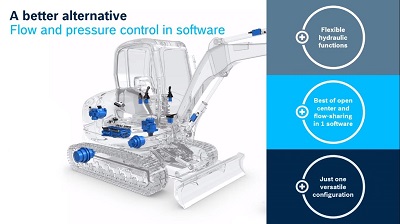

A better alternative, said Dreher, is electronification of hydraulic components. It lets OEMs build a machine with simple and flexible hydraulic functions, combine the best of open-center and flow-sharing in one software platform, and manufacture only single type of machine that can be preset one way or another, according to the customer’s choice, without compromises.

The eOC pump – the central component

A new electrohydraulic system moves control functions from the hydromechanical controller to software. The Rexroth eOC (electronic Open Circuit) portfolio includes software and hydraulic components for dynamically controlling work applications and travel drives. Controlled via a CAN interface, eOC software makes it possible to set various control parameters flexibly during operation. With hydromechanical control functions and interfaces moved to the software, control modes can be individually changed and combined during operation and pump dynamics can be variably set.

“Today, for different applications, different tasks and different control strategies, we have a wide range of hydromechanical controllers. These often come in combination and therefore are cost intense. Finding the right setting for each controller has always been a compromise. And once a setting has been defined, this could not be changed in the field. With eOC, we have now managed to transfer all of today’s pump control functions into software. This enables better control quality and unlimited flexibility to achieve extremely individual machine settings,” Dreher explained. “And what’s more, parameters can be changed on an incremental scale by the operator, right in the cabin.”

With electronic closed-loop control, the BODAS eOC pump control software requires an electrohydraulic control valve on the pump, a swivel angle sensor, and pressure sensor on the pump outlet. For electronic load sensing, an additional pressure sensor for the load pressure must be installed at the LS port of the main control valve. The software itself runs on a dedicated control unit and processes pressure, swivel angle and rotational speed information. And as an output, it generates a PWM current for the pump control valve.

Thus, pressure, torque, flow and swivel angle are controlled independently of each other in an electronically closed control circuit, so the pump behaves optimally as part of the entire hydraulic system. And because the eOC architecture allows for dynamic control of pressure, swivel angle and torque gradients, it enables much smoother and gentler motion, especially at the start of a movement. Via the CAN bus interface, setpoint values and parameters can also be adjusted dynamically to allow additional functions and to adapt machines to cope with specific customer requirements and work tasks.

The eOC software can be installed on a Rexroth BODAS controller or a third-party controller. It constantly adapts hydraulic power to the available engine torque and thus allows dynamic, precise work functions, which ultimately increase the overall productivity of the machine. It optimizes energy consumption of the entire hydraulic system, resulting in lower fuel consumption or, in the case of electrified machines, better battery use.

Further developments

As a scalable solution, the Rexroth eOC portfolio allows step-by-step implementation — from the electrohydraulic eOC pump to the option to cover the entire hydraulic system, including an eOC main control block and an electric joystick.

Auto-calibration, where a component calibrates within the machine itself, is another new eOC function. Instead of performed statically at the end of an OEM’s production line, calibration is instead carried out cyclically while the machine operates. The eOC software records specific calibration information at start-up and during operations. Up-to-date data which, for example, take into account aging effects or temperature differences, are recorded and parameters automatically adjusted accordingly. This increases the reproducibility of behavior, enables full use of pump power at all times, and supplies precise pump status information for further processing on the machine level.

Travel drives

The Rexroth eOC architecture also allows a new approach when it comes to travel drive systems, especially for compact machines. Based on a secondary control concept, the eOC combines the functionality of a closed-circuit travel drive with the physical layout of an open-circuit drive which only requires one pump for travel and working functions.

As a result, all travel and work functions can be combined in one hydraulic circuit — all rotating consumers are connected directly to the pressure line. A secondary logic system with no additional directional valves controls the hydraulic motor displacement and output torque to achieve the desired rotational speed.

The eOC travel concept requires fewer components and simplifies the hydraulic architecture, as travel direction valves and brake valves are no longer needed. In addition, the combination of working and travel functions in one hydraulic circuit allows the recovery of hydraulic energy during braking or lowering and, thus ensures, that the optimum use is made of the drive power.

Proven concept

Commercial machines already benefit from the new eOC system. They include a compact excavator developed for demanding excavation work, which entered mass production in the first half of 2021. This operating mode allows maximum pressure and torque as well as maximum pressure gradient dynamics, for example when emptying the shovel. At the same time, the machine has a fine mode allowing jerk-free, smooth operation, for example when laying pipe.

The eOC architecture is also ideal for use in wheeled excavators. To adjust the power in these multifunctional machines to suit the particular task, numerous valves were needed in the past. The switchover to the eOC architecture significantly reduces the hardware outlay, minimizes costs and avoids potential sources of error in valve switching.

Bosch Rexroth

www.boschrexroth.com