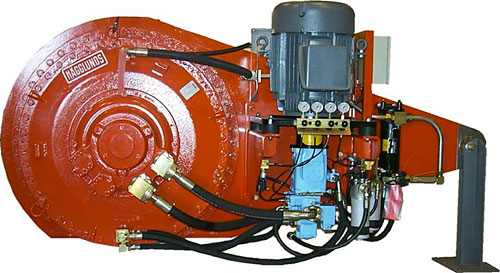

The Hägglunds TADS unit represents maximum performance in smallest footprint possible by creating a self-contained drive package where the torque arm serves as the framework for mounting the complete drive system.

This allows the TADS unit to occupy approximately the same space as a normal low speed, high torque motor with torque arm mounting, but eliminates the external equipment such as gearboxes or heavy pedestal foundation elements, which are no longer required. This means that customer machines, and in some cases the facilities that house them, can be smaller, lighter and simpler without sacrificing the power to handle heavier workloads making the TADS system a great hydraulic drive system for industries like mining and bulk materials handling.

The TADS unit offers machine designers the flexibility to integrate the power of Hägglunds hydraulic drives into the widest range of industrial applications by offering nine different modular configurations with both spline and shrink disc coupling options.

Easy to install and use

The TADS unit comes preassembled and ready to mount on the process machinery’s drive shaft, saving installation time and costs. It can be installed using either an internal spline or hollow shaft with shrink disc couplings — and none of the extra hoses or control cabling typically required with a conventional power unit and motor.

All Hägglunds motors and drives are engineered to deliver maximum torque from zero speed with infinitely variable settings. Plus, they are manufactured to deliver high reliability and long service life, protection from shock loads and operation of infinite start, stop and reverse that does not damage the system.

The Hägglunds TADS unit features extremely fast hydraulic pump compensators that can reduce the wear and lengthen the life of any machine. Load-sensing and power-limiting tools enable operators to intelligently sustain peak levels of operation that outperform other systems — boosting machine uptime and helping reduce total cost of ownership.

Bosch Rexroth

www.boschrexroth-us.com