By Josh Cosford, Contributing Editor

I’ll cut to the chase; the best days for the hydraulic vane pump are likely behind us but they’re not quite ready for extinction. Let me tell you why I feel this way. Just like much of technology from the early days of the twentieth century, the vane pump came about as inventors searched for “the better mousetrap.” There were many ways to create the pressure and flow required for a hydraulic system, and alongside the piston and gear pump designs, the vane pump turned out to be a fantastic option.

For many of the early decades, hydraulic systems could not function higher than 2,000 psi. This suited the vane pump perfectly, mainly the pressure-compensated vane pumps that arrived later in the game. The vanes take advantage of hydraulic pressure to force themselves against the cam ring to seal more effectively. However, as pressure rises, the force against those vanes becomes excessive, increasing friction and wear.

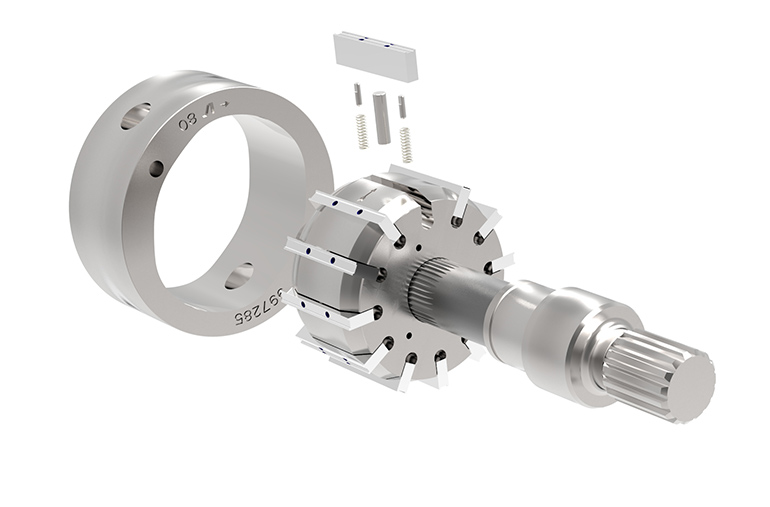

Vane pumps also benefited from a design allowing the cam ring to move radially relative to the shaft rotation. By attaching a pressure compensator to one side, an increase in pressure above the opposing bias piston’s spring force will result in the cam ring moving towards its center of rotation, effectively reducing pump displacement.

The pressure-compensated vane pump has dominated the machine tool industry, offering a quiet, somewhat efficient unit able to operate jaws or clamps at relatively low pressure. Even today, CNC machines everywhere use these pumps, their high demand maintaining their economical price point and quick delivery.

Advances in technology and materials helped the modern fixed-vane pump achieve performance over 5,000 psi. A combination of hardened steel, tighter tolerance and a pitch in vane angle gives the pump higher durability when exposed to the upper reaches of hydraulic pressure. However, variable displacement technology never caught on for these high-pressure pumps.

Most vane pumps are moderately priced, splitting the gap between the economical gear pump and the pricy piston pump. However, the vane pump’s modest advantages of low noise and slightly improved efficiency make them hard to justify over a gear pump, in most cases. As a result, their popularity has waned as consumers gravitated towards the inexpensive gear pump for low-end systems or the high-performance advantage of the piston pump.

Not all is lost for the vane pump, however. Besides their lock on the machine tool industry, they are ideally suited for other niches better than their counterparts. Hydrostatic bearings use hydraulic pressure to support large diameter or high-speed bearings, providing lubrication and a liquid bearing surface. The high-pressure fixed vane pump provides up to 5,000 psi in some applications while being quieter and less expensive than the piston pump option and offering better contamination resistance.

Fixed vane pumps have received more attention recently because, combined with closed-circuit drive systems, they provide a quiet and efficient closed-circuit pressure and flow control. Unlike the pressure compensated pump that reduces displacement to control pressure, the closed-circuit pump system uses pressure transducers to measure pressure, and then the PLC reduces the electric motor’s speed to exactly match the desired output pressure. With this type of technology behind it, the vane pump is not likely going away.