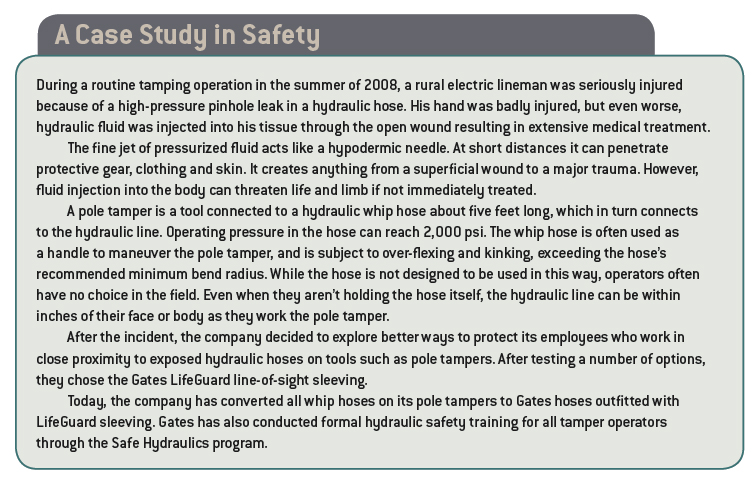

Protective covers for hydraulic hose assemblies are taking on a whole new meaning as line-of-sight sleeving becomes a safe alternative for protecting operators and personnel.

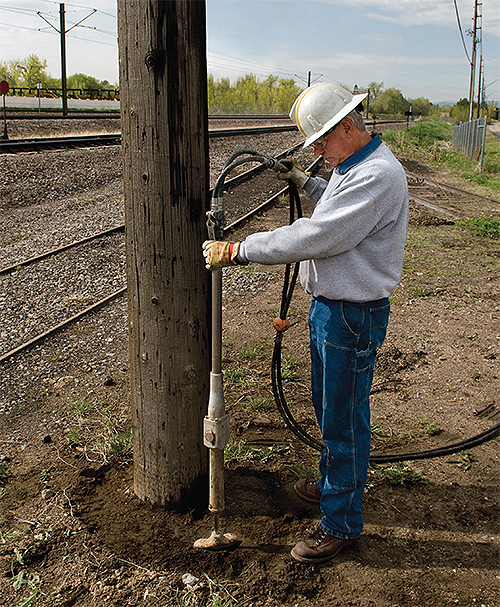

Protective covers for hydraulic hoses are still used to protect hoses on mobile construction and mining equipment. However, with the need for higher-pressure systems and more compact machine designs, there is an increasing need for ways to safely protect machine operators and personnel from catastrophic hydraulic hose failure.

The first and best way to protect a hose assembly, especially from abrasive wear, is to route the hoses to avoid hose-to-hose and hose-to-metal contact. A second option is to specify a hose made of special hybrid compounds. Some new hybrid cover materials have been tested to last up to 300 times longer than standard rubber covered hoses.

To further protect hydraulic hoses from external damage and wear, you can use several different types of hose guards or sleeves:

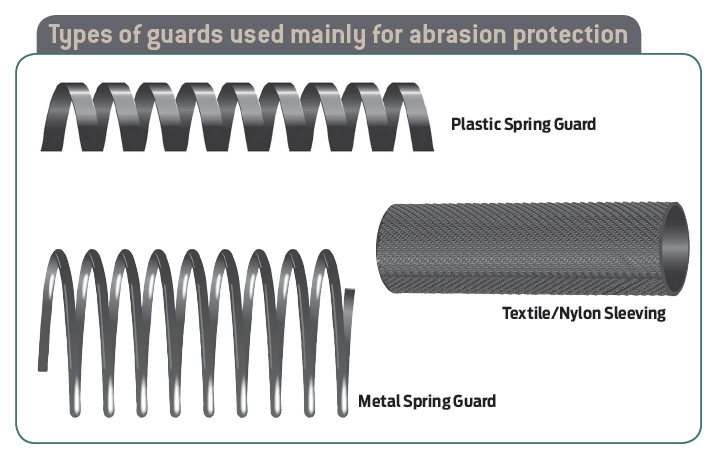

Metal Spring Guard – This is often used where an exposed hose can encounter flexing, twisting, kinking, tensile or side loads, a tight-bend radius and/or vibrations. The metal spring guard needs to be fitted before the hose is assembled.

Plastic Spring Guard – This flat, plastic guard is also used on exposed hoses, but has the added advantage of being able to be fitted after the hose has been assembled and sometimes after it has been attached to the equipment.

Textile/Nylon Sleeving – This type of sleeving is often used on hoses inside the equipment or in places where abrasion is likely. Textile sleeving offers excellent wear resistance and can help reduce the amount of oil spillage.

Protecting From Catastrophic Failures

While these sleeve covers can protect hydraulic hoses from abrasion and cuts, they typically offer little or no protection from hose bursts and pinhole leaks. Excessive pressure surges, flexing, kinking, crushing or exceeding the minimum bend radius can cause a burst away from the hose ends. Pressure surges that exceed the hose’s maximum operating pressure rating can lead to reinforcement failure. Excessive flexing, kinking and crushing can cause reinforcement fatigue and eventual failure. Bending the hose tighter than recommended will place excessive stress on the reinforcement that could open large gaps between strands of reinforcement and drastically reduce the hose’s ability to withstand pressure.

A pinhole leak in a hydraulic hose under pressure can release toxic fluid at more than 600 ft/sec – close to the muzzle velocity of a gun. Although the hose’s high-tensile wire-reinforcement structure bears the brunt of the pressure, the inner tube itself has to bridge the gaps in the braid, formed when the hose is bent and stressed. If the compound isn’t strong enough, it will be blown through the gaps in the braid, which can cause a scissoring effect and cut a hole in the tube, causing a pinhole leak. The fine jet of hydraulic fluid at high pressure can act like a hypodermic needle, penetrating both protective clothing and skin.

LifeGuard sleeving protects operators from 3,000 psi pinhole leaks and 6,000 psi bursts on -4, -6 and -8 hose sizes. The sleeving is compatible with a wide range of fluids, including environmentally friendly liquids and biodiesel fuel. It protects up to 212° F, the SAE standard for most industrial hydraulic applications.

To protect operators of hydraulic equipment from catastrophic hydraulic hose bursts or pinhole leaks, several hose manufacturers have developed their own versions of a safe “line-of-sight” nylon sleeving.

One example is the LifeGuard sleeve manufactured by Gates. The key design feature is a double layer of nylon material. Separate from one another, the two layers are able to slide and move independently to control hydraulic failures. The two sleeve layers are continuously woven together at the same time, one inside the other, but they are not attached to one another.

The sleeve is slipped onto the hose and clamped and secured at each end with special channel clamps. The clamps allow leaking fluid to escape, so the fluid won’t collect behind the sleeve and cause it to burst. Fluid leaking past the clamps lets the operator know that there’s a leak in the hose.

The inside sleeve layer is made of a tightly woven filament nylon fiber that elongates or stretches up to 20%. By stretching, it can absorb the energy of a burst or pinhole leak. The outer sleeve is a textured nylon material that further helps to contain escaped fluids and redirects them to the clamped ends of the hose for release. The outer sleeve is resistant to abrasion, but is not specifically designed for abrasive environments. The safety of workers within a three-foot line-of-sight of a burst or pinhole leak is the main benefit.

The current standards and specifications relating to hydraulic hose protection are vague. ISO 3457 and EN474-1 both state that, “Hydraulic hoses containing fluid with a pressure of more than 5MPa (50 bar) and/or having a temperature over 50° C, and which are located within 1.0 m of the operator, shall be guarded.” So the standards clearly don’t specify how the hoses should be guarded.

Some industries, like mining, have their own specific standards. All mining industry equipment must conform to Mine Safety and Health Administration (MSHA) standards and be certified. MSHA’s Accident Prevention Program simply says, “Install abrasion protection such as spiral wrapping, sleeves and guards.” ISO and European standards don’t specify a test method for sleeving products either.

Discuss this on the Engineering Exchange:

Gates Corporation

www.gates.com

::Design World::