Contributed by J. Eric Freimuth, Hydraulic Training Associates

Many of the failures in a hydraulic system show similar symptoms: a gradual or sudden loss of high pressure, resulting in the loss of power or speed in the cylinders. In fact, the cylinder may stall under a light load or may not move at all. Often the loss of power is accompanied by an increase in pump noise, especially as the system tries to build up pressure. Any major component, including the pump, the relief valve, directional control valve, or the cylinder, could be at fault.

In a sophisticated system, other components could be to blame, but this could require the service of an experienced technician. By following an organized step-by-step testing procedure in an orderly fashion, the problem can be traced to a general area, and then if necessary, each component in that area can be tested or replaced.

In this article though, we want to discuss the safety tips concerning cylinder design and use. What are some of the suggested things we should be looking for when selecting the right cylinder for the job? Answering these questions before installation is a start to safe and optimal cylinder design.

- Is the cylinder rated for the work to be done? Using the F = P x A formula (Force = Pressure x Area) will ensure that the cylinder is sized properly to do the work at the required system pressure.

- Is the cylinder designed to handle the load? With so many manufacturers today, choosing a cylinder that will hold up to the load requirements is important. Be sure to evaluate the seals and guide bands being used for bearing loads. Agricultural equipment typically uses ag-type cylinders that feature cast end covers bolted together with all thread and nuts onto a honed tube. They also typically use O-rings for seals. These cylinders generally operate around 1,500 to 2,000 psi and are designed to be either quickly resealed or thrown away. Using this type of cylinder in a construction application would prove to be dangerous and self-defeating as it would be short lived for the work to be done and may not hold up under the load requirements.

-

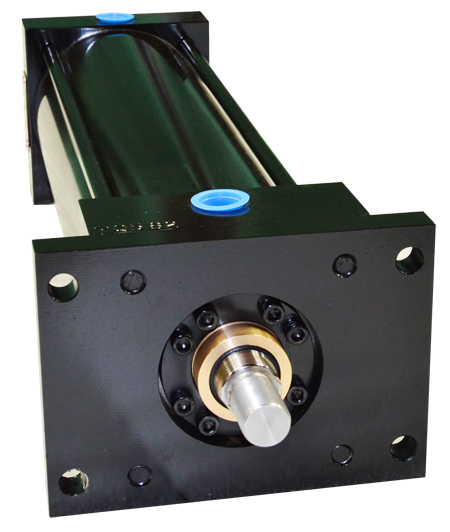

Welded hydraulic cylinders, like this one from Yates Industries, are better suited for mobile machinery. Tie-rod or welded? When is it appropriate to use a tie-rod cylinder or a welded cylinder? The typical response is that manufacturers of stationary equipment generally rely on tie-rod cylinders, as they can be configured to fit most unique applications and have many applicable valving blocks, making them simpler to configure to machinery. This reduces other possibly needed valves to accomplish work desired and helps to reduce costs. Rated to NFPA standards, tie-rod cylinders are easily inter-changeable with other manufacturers. Welded cylinders are most common in mobile equipment where weight and size of application work needs can be considered. These heavier duty designs are usually rated to 5,000 psi or higher. Featuring a barrel that is bolted or welded directly onto the end caps, these designs do not require tie-rods, so thus are stronger and more resilient in harsher environments.

Above all else, it is important to be sure to use a cylinder that is rated for the job. Choosing a cylinder because of cost rather than design can be a mistake in many ways. Seals, wear bands, shaft seals, and porting all play an important part of selection.

Hydraulic Training Associates

htahydraulics.com

Hi,

My name is Ben an Engineering Student. I do a research on Hydraulics operations and maintaining it. Hydraulics operate under enormous amounts of pressure. Due to a combination of factors, these components will wear over time, creating serious problems and potential risks. You have posted a good article and I learned some good info from the same. Thanks for the article there was one more article that has some good pointers https://www.hydramech.com.au/managing-hydraulic-components-wear Thought of sharing the same.