Rexroth’s robust RC4-5 controller offers the optimal balance of power and flexibility to maximize both hydraulic component and overall system performance. However, the secret to realizing best in class electrohydraulic control performance is how the RC4-5 drives proportional solenoids.

The RC4-5 offers four fast and accurate Pulse Width Modulated (PWM) driver outputs with closed-loop current control. Closed-loop current control compensates for the real world changes in voltage and resistance to provide repeatable performance from machine to machine, day-in and day-out. Adjustable parameters for solenoid current, linearization and PWM frequency easily adapts the RC4-5 to a wide variety of 12- and 24-volt electro-proportional components. Finally, software algorithms embedding Rexrothâs considerable knowledge of drive and control enables the RC4-5 to smoothly and accurately unleash the phenomenal power of hydraulics to meet the performance demands of todayâs mobile equipment.

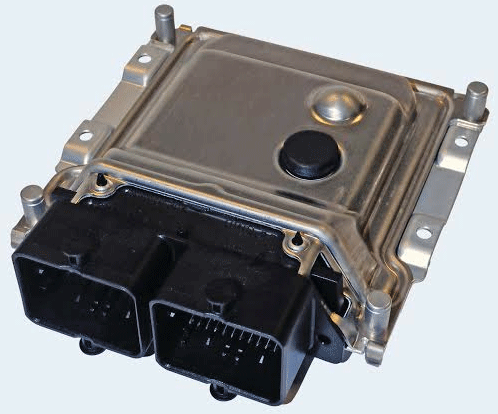

While controlling hydraulic power is often a core requirement for mobile equipment, the RC4-5 also provides a flexible set of inputs and outputs to support a wide variety of work, travel, auxiliary and operator functions for system integration. Many common sensors for force, speed, pressure, position and temperature measurement may be directly connected to the controller while two CAN bus channels offer communication gateways to a wider array of devices including joysticks, displays and engines. The RC4-5âs compact envelope of approximately 5â X 6â X 2â also makes this controller a good fit for mobile equipment where installation space is usually limited.

The computational power of the RC4-5 is also a good fit for the increased features, functionalities, and performance specifications to compete in the quickly evolving global mobile equipment market. With its 80 MHz, high performance 32-bit processor, the compact RC4-5 can easily handle multiple simultaneous complex control tasks. This often relieves the concerns of project managers and engineers undertaking a new software development.

Software development is executed using standard C/C++ program language which leverages common knowledge and development tool chains already existing in industry. To boost development speed and application performance, Rexroth offers their C-API, C Application Program Interface which encapsulates basic operations, fault detection, diagnostics and sophisticated control techniques for hydraulics in an easy to use library. Included with the C-API is the interface for Rexrothâs standard powerful mobile electronic support tool BODAS-service.

The BODAS-service tool allows controllers to be FLASH programmed, configured, optimized, diagnosed, and data logged in a user friendly environment. Since this tool supports the general Rexroth product program, it is already used by factory and service technicians worldwide.

Rexroth

www.boschrexroth.com