Every three years, the fluid power world comes together at IFPE. This year’s event will be at the Las Vegas Convention Center from March 7-11, and it will offer designers the opportunity to see what’s new with pressure transducer technology. Here you can learn how they are constructed and used on mobile machinery. Below, you will find a listing of IFPE 2017 exhibitors who will be displaying their pressure transducer technologies.

Every three years, the fluid power world comes together at IFPE. This year’s event will be at the Las Vegas Convention Center from March 7-11, and it will offer designers the opportunity to see what’s new with pressure transducer technology. Here you can learn how they are constructed and used on mobile machinery. Below, you will find a listing of IFPE 2017 exhibitors who will be displaying their pressure transducer technologies.

The measurement of pressure had once been a monopoly of Bourdon tube pressure gauges, and if you wanted to check the pressure at any location in a fluid power circuit, you had to go right to the source to install a pressure gauge at the location you wished to measure. The invention of test points and micro-bore hoses allowed for some distance between point of measure and point of reading, but reliable and accurate readings were still limited.

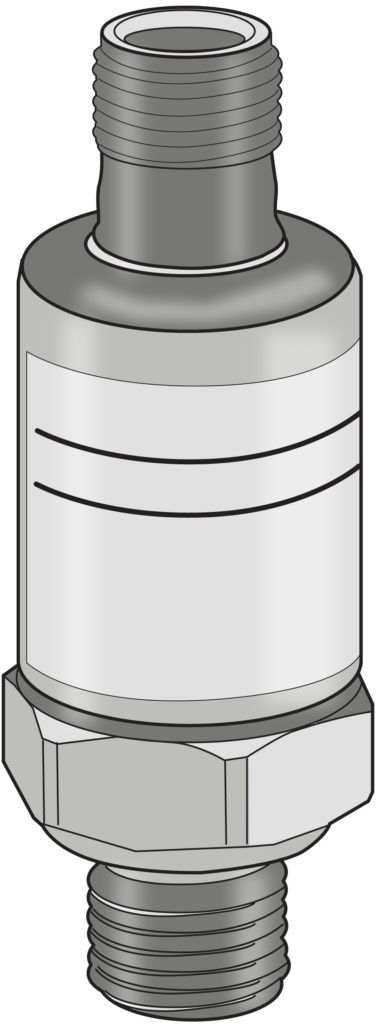

The proliferation of electronics into fluid power has changed the way we can measure pressure, and has enabled versatility not enjoyed previously. Pressure transducers are solid state, meaning there are no mechanical moving parts, instead using something called a strain gauge which changes in resistance when warped out of shape by pressure. Their solid-state nature means they are very reliable, often lasting millions of cycles.

Pressure transducers require a power source to give their output signal, usually a 24-V input. Their outputs are typically one of the standard control signals, such as 0-10 V or 4-20 mA et al. This signal can be fed into a PLC for feedback of closed loop control, such as servo-pump pressure control, or the transducer signal can simply plug into a digital display.

Transducers are typically male-threaded and plumbed into any location where you wish to measure pressure. When used in conjunction with a PLC, the basic plug-in type with a M12 or DIN connector is all that is needed. The transducer must be chosen for the appropriate pressure range it will measure, especially if you wish it to be accurate. For example, if you are measuring around 100 psi with a 0-10 V transducer, using a 1000-psi transducer will only ever read 1 V, leaving the rest of the pressure range unused.

Pressure transducers are also available with on-board electronics, including displays and switches. One device, for example, can display the pressure, provide a handful of switch’s outputs with configurable switch-back points, and also provide its analog output for a PLC to use as well. With the cost of electronics at an all-time low, they’re not as expensive as you would think, either.

Pressure transducer manufacturers & suppliers at IFPE

Balluff Inc. G70307

Bosch Rexroth S80214

Gems Sensors & Controls S81355

Hydronit Americas S82855

Nason S80714

Noshok S83146

Orange Research S83656

Poclain Hydraulics S81640

Rota Engineering S84130

Suco Technologies S83351

Turck Inc. S83230

WIKA Instrument Corp. B90425

Winters Instruments S83756