Agriculture continues to improve with new technology for more precise seeding and fertilizing operations. The latest high-efficiency air seeders and fertilizer applicators designed and manufactured by the Salford Group incorporate Zero-Max Overhung Load Adaptors. They handle high speed and provide impeller support for the optimal operation of the hydraulic motor and the system’s blower chamber for seeding and fertilizing.

Salford air boom applicators (like the 9620 or 6700 designed for use on John Deere and CaseIH equipment) are engineered for high rate fertilizer application, but to meet the needs of today’s precision applicators, they also need to vary application rates, quickly and accurately. To facilitate this, the system’s blower fan must operate at a regulated high speed, according to the amount of fertilizer being applied. With a speed range up to 4500 rpm, the Overhung Load Adaptor ensures that the hydraulic motor delivers smooth rotation to the impeller so the blower consistently delivers the required air flow. These Salford tools handle a variety of seeds and fertilizers over a wide range of application rates. The Overhung Load Adaptor ensures that the system performs at your chosen rate.

Additional important benefits include support for the impeller while extending motor bearing and seal lifetime. The Overhung Load Adaptor simplifies the construction of the blower mechanism as a proven solution while saving space. This compares to previously using a coupling and a custom fabricated support device, which is time-consuming and costly to produce and assemble. Also, the Overhung Load Adaptor provides a contamination barrier by separating the hydraulic motor from the blower chamber. The benefits are the hydraulic motor seals are protected, the hydraulic fluid is away from the blower chamber, and the Overhung Load Adaptor interfaces with and seals the blower chamber.

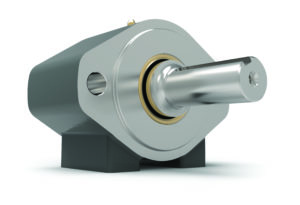

These latest model Salford fertilizer applicators incorporate the Model 200 Overhung Load Adaptor with a closed end keyseat for retaining the key when installed. Pre-greased, they have metric input and output shafts with an adaptor plate included to facilitate motor mounting. The model 200 is one of over 1300 designs offered by Zero-Max to meet new and unusual overhung load system requirements. These designs include custom inverted bearings and multiple lubrication ports that increase the Overhung Load Adaptor’s load capacity, bearing life, and smooth system performance.

Designed for either face or foot mounting, Overhung Load Adaptors are available in over 50 standard models. SAE mounts available include A, B, C, D, E, and F mounts with 2 or 4 bolt mounting flanges. They are also available with many shaft variations including splined, threaded, tapered, and extended output shafts. Special input bores and housing modifications are available as well.

Manufactured to ISO 9001:2015standards, Zero-Max Overhung Load Adaptors are ruggedly built, with shafts precision machined from high quality 130,000 PSI stress-proof steel. All custom Overhung Load Adaptor designs include a detailed CAD approval drawing submitted prior to manufacture.

In addition to agriculture equipment applications, there are many other applications subjected to difficult and hostile operating environmental conditions. Zero-Max Overhung Load Adaptors are widely used in workboats, recycling systems, forestry shredders, road paving equipment, industrial conveyor drives, and many others where hydraulic systems require stability and shaft seal protection.

Zero-Max

www.zero-max.com