Nearly 30 years ago, the late Bob Koski of Sun Hydraulics made a provocative presentation titled “Fluid Power Education – What went wrong?” He noted that every mechanical and electric engineer learns about electrical power actuation and motion control, but only about 5% of mechanical engineering graduates learn about fluid power actuation and control.

The technological vacuum that resulted, he said, makes it difficult to convince potential users of the advantages that fluid power offers over alternative means of mechanical power transmission. That pretty much still holds true today.

Prof. Andrea Vacca, Maha Fluid Power Faculty Chair at Purdue Univ., is trying to overcome such hurdles with innovative ways to teach fluid power to the new generation of engineers.

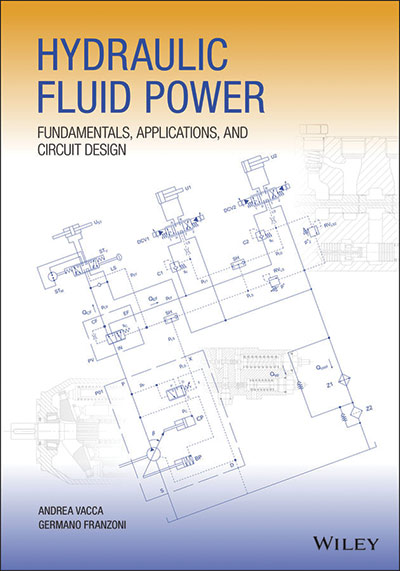

One fundamental problem is a lack of up-to-date fluid power textbooks, as most are at least a decade old. Vacca and Dr. Germano Franzoni recently authored “Hydraulic Fluid Power” to fill that void. The content not only focuses on basic principles, components, and the design of complete hydraulic circuits, it also delves into practical concepts for controlling state-of-the-art systems. Print and E-book versions are available at www.wiley.com and Amazon.

Another challenge is that many universities shy away from fluid power because teaching it requires large and expensive labs. In addition, fluid power can be seen as a design discipline and unfortunately, design classes have been eliminated from the curriculum of many schools or relegated to electives and special or senior-level projects.

Yet academic and industry leaders agree we need flexibility and hands-on experience to teach fluid power. So one bottleneck lies in the design and cost of modular fluid power training platforms, or simply trainers.

“The problems with current trainers are that they take up a lot of space, they’re expensive, safety can be an issue, and the experience for students in many of them is not that great,” said Vacca. Most don’t give the perception of the latest technology, and they’re not versatile enough to encompass a wide range of experiences. Commercial trainers tend to be professionally built and are good for simple circuits and troubleshooting. But they offer limited flexibility and aren’t particularly user-friendly.

Thanks to financial and technical support from Parker Hannifin, Vacca’s team spent countless hours to develop a next-generation trainer that overcomes many of these limitations. The Purdue hydraulic trainer includes a touchscreen display, numerous position, pressure, flow and speed sensors, and electronically control valves, along with a pressure- or flow-controlled supply. With it, users can explore wide-ranging control options like velocity, force, torque and position control; resistive and overrunning loads; and set-ups with single or multiple actuators. The result is more than 50 lab experiences covering basic to advanced mobile and industrial hydraulic concepts — everything from load-sensing systems and proportional hydraulics to troubleshooting for aeration or cavitation.

The design proved to be a success with students. Nonetheless, the trainers are available to relatively few users, and cost and space are still issues. And it doesn’t meet today’s expectation that students should be able to learn on a computer. If we don’t accept that, we won’t get the new generation to be passionate about fluid power technology, said Vacca.

There are several E-learning software packages on the market that attempt to simulate systems, but they don’t offer a hands-on experience. Thanks to extensive development and programming work, Vacca’s team has created the Maha virtual hydraulic trainer to bridge that gap. The sophisticated virtual reality tool exactly replicates the physical Purdue hydraulic trainer — even to the point of generating sound effects based on noise recorded under actual operating conditions. It uses object-oriented programming and a graphical user interface that lets students follow schematics, connect components, decide on measurement points and sensor placement, and so on. And then run simulations and generate technical reports.

How well does it work? Since 2020, over 90% of undergraduate and graduate students gave it positive reviews. The virtual trainer requires much less space, is economical, safe, and available to many more users. Plus it’s pandemic proof.

Modern hydraulic trainers help fulfill the goal of attracting engineering students to the fluid power discipline, said Vacca. The Purdue hydraulic trainer is available to universities, thanks to Parker Hannifin; and a version of the virtual trainer is ready for distribution.