Integrated hardware and software replace traditional mobile-hydraulic control systems.

Today’s mobile-equipment manufacturers, for the most part, face a number of common challenges. OEMs want to streamline engineering and production processes yet build machines that are highly efficient, reliable and productive. And, increasingly, their customers want to monitor and track how these products operate—to ensure they live up to expectations and generate a healthy ROI.

To support those goals, Parker Hannifin, with headquarters in Cleveland, recently upgraded its range of mobile-equipment electrohydraulic controls with IQAN Connect, an electrohydraulic motion-control platform that bridges machines to the IoT world. According to the company, IQAN Connect dramatically reduces development time, optimizes equipment performance and gives OEMs and fleet managers a better handle on how machines are actually used.

To support those goals, Parker Hannifin, with headquarters in Cleveland, recently upgraded its range of mobile-equipment electrohydraulic controls with IQAN Connect, an electrohydraulic motion-control platform that bridges machines to the IoT world. According to the company, IQAN Connect dramatically reduces development time, optimizes equipment performance and gives OEMs and fleet managers a better handle on how machines are actually used.

IQAN Connect, explained Johan Liden, IQAN product manager at Parker’s Electronic Controls Division, is a seamless “digital ecosystem” that ties together the hydraulics and electronic-control hardware and software inside a machine but also, via the Internet, provides access to the cloud for remote monitoring and asset management.

“One way to look at IQAN is in terms of the whole initiative around IoT as it pertains to electrohydraulics in the control space,” said Robert Lorance, strategic business development manager. It focuses on three areas. First, the platform relies on “intelligent” components with on-board electronics and sensors that communicate with each other and with higher-level systems via a standard SAE J1939 CAN bus, he explained.

“Second, our IQANdesign tools offer the next generation of control software with lots of functionality and are easy to use,” Lorance continued. “And third is our connectivity initiative around how we take data, get it to the cloud and then begin the process of moving from information to insight.” Equipment builders and operators can use that information to benchmark machine performance and output—and ultimately leverage that knowledge to improve productivity, reliability, efficiency and overall economics, he said. Here’s a look at some IQAN Connect highlights.

Smart components

Parker engineers have developed an extensive suite of IQAN-compatible products over the past 20 years. It includes hydraulic components like mobile pumps, valves, motors, cylinders and accumulators, as well as electronic hardware like operator displays, joysticks, cameras, and IoT gateways. In addition, a family of high-performance controllers provides precise, real-time management of mobile electrohydraulic systems. They support tasks that demand high levels of computing capacity as well as functional safety applications.

The components all run on customizable IQAN software and standard J1939 communication networks for straightforward system integration, resulting in complete machine control and asset management. “IQAN Connect, in its most simple form, is all about plug-and-play,” said Lorance. “Our components are connected in the IQAN software and recognize each other and, for the engineer, it’s easy to set parameters, get the system up and running, and then send that information to the cloud.”

“These intelligent components also hold significance around engine management,” added Anthony Vaughan, vice president of technology and innovation. For instance, the new P1M piston pump with built-in electronic controls permits advanced closed-loop control in demanding applications, while simplifying the surrounding systems with a local controller for the pump. “It takes information from the engine and other components via the J1939 CAN bus for operations like torque control and torque summing. Optimizing flow control and pressure control ensures you’re not stalling engines while you’re maximizing your torque curve and pump flow. That’s really the key for fuel efficiency.”

Simplified design

IQAN Connect also simplifies the development process and gives engineers more design flexibility, which in the end leads to both faster turnaround and better-performing machines, they explain. Parker’s newly released IQANdesign 5 software tools include an intuitive graphic interface, a component library and drag-and-drop features that do away with previously tedious engineering tasks.

A building-block approach simplifies controls design and layout without requiring extensive programming skills to effect advanced machine functions. It also cuts the time required for prototyping, testing and validation. For more details, see the accompanying sidebar, “Building hydraulic-control systems with drag-and-drop ease.”

Cloud access

Another significant feature of IQAN Connect is that components and controllers, via an on-board gateway, provide two-way communication with the cloud. All data available on the J1939 CAN bus, including information on the engine, transmission, sensors or specific hydraulic components can potentially be tracked and displayed as a web application or even on a mobile phone.

Engineers can tap into this operating data and use advanced statistical programs to fine-tune the system and improve performance and efficiency. Changes and updates can be quickly downloaded to the machine’s IQAN master via a laptop, or remotely via a communications link. And for security, multiple levels of access can be customized as needed, said Lorance.

Likewise, users or third-parties can access the data for troubleshooting or apply the information to maintenance software, analytics programs and tracking tools. For instance, customized dashboards can provide diagnostic information to operators and fleet managers, send alerts as needed, and enable predictive maintenance that reduces downtime, maximizes ROI and improves safety and productivity.

Another key facet of the platform is IQAN Asset Monitoring. This enterprise-software tool connects ground-based machines to the cloud to provide vital insight on the overall performance of an entire fleet, noted Nick White, senior systems engineer.

For example, a fleet-overview screen displays the location and status of every networked machine. Users can quickly browse the general status of all the equipment or drill down to a specific machine. “A fork truck, for instance, could send process data such as the total weight it moves over the course of day, and the total number of lifts—information valuable to a fleet owner,” he stated.

“And this data can be used in more-complex ways, such as determining the distribution of bin weight picked up from 0 to 100 pounds, 100 to 500 pounds, and so on. This gives insight into how each machine operates. We can also compare how one operator is performing against the others,” said White.

This gives users the power to scale a solution and make it unique and operator specific, whether the focus is on cost, productivity or downtime, said Lorance. The ability to extract that data and gain a deeper understanding of machine operations is a real game changer, he emphasized.

“Customers no longer have to be a major OEM to have insight,” added Jacob Haas, vice president of marketing of Parker’s Hydraulics Group. “Literally anyone with this type of control system, even a small OEM, can have data insight, and that will truly be a differentiator. We can now put this in the hands of our operators and help them become more efficient and grow their business, too.”

Diverse applications

The IQAN Connect system is suited for a wide range of construction, forestry, agricultural, material-handling and mining equipment. For example, it’s been used on telehandlers, refuse trucks, crop sprayers and rock drills, just to name a few.

Parker’s experts expect mid-size machine builders to have the most interest in the entire IQAN Connect offerings. And smaller manufacturers, often with the help of local distributors, will also take advantage of IQAN’s ease-of-use and plug-and-play features. Large OEMs tend to have proprietary control systems, although IQAN is compatible with Tier 1 systems using standard J1939 networks.

“There’s a tremendous amount of interest with the mid-tier segment in terms of solutions that they can scale and run with. It is truly intuitive how customers can quickly customize their designs, launch simulations, do calibration and troubleshooting. It is really made for the mid-tier and lower tier of the market,” said Haas.

“And the focus may be different for most every customer,” he added. In some cases, it is about fuel efficiency, for others downtime is just not acceptable. Or the focus might be on lowering engine speeds, reducing emission, or eliminating non-value-added tasks to raise productivity and save money.

“Our customers’ value propositions are often very unique and very tailored. But at the end of the day, it’s all about our ability to either help our customers save money or help our customers make money,” said Haas. And the ability to capture data and do the analytics will let engineers gain insight in areas like reliability, predictive maintenance, controllability and safety, he said. “That, in turn, will help us design better next-generation products that ultimately benefit the customer.”

Parker Hannifin

parker.com/iqan

Building hydraulic-control systems with drag-and-drop ease

The time it takes to engineer a machine and get it to market is one of the most important contributors to an OEM’s return on investment. It is primarily determined by design time, application programming, simulation, testing and creating all the necessary documentation. IQANdesign software, a key part of the IQAN Connect system, reportedly streamlines that process to significantly reduce engineering time and expense.

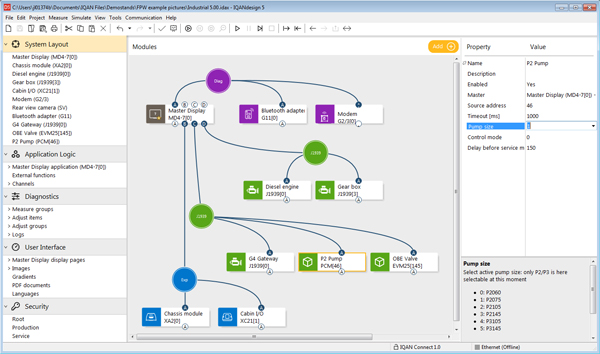

The latest version, IQANdesign 5, is a high-level graphical design tool that simplifies control-system application development for mobile machines, explained Johan Liden, IQAN product manager. Five different sections let engineers define a machine’s control system, specify application logic, and set up diagnostics, user interfaces and system security, he said.

The latest version, IQANdesign 5, is a high-level graphical design tool that simplifies control-system application development for mobile machines, explained Johan Liden, IQAN product manager. Five different sections let engineers define a machine’s control system, specify application logic, and set up diagnostics, user interfaces and system security, he said.

Typically, they first select appropriate modules from a database in the IQAN Connect library. These represent hydraulic components, engines, gearboxes, electronic hardware and diagnostic interfaces like Bluetooth adapters and modems. Users drag-and-drop the modules to configure the system, and then connect them with a suitable CAN bus. Control modules serve as a standalone controller or CAN bus master, and a gateway module sends data to the cloud.

Once the layout is set, canned software routines available within IQAN let developers quickly program operating functions and optimize sophisticated applications. A wide range of predefined building blocks include options such as closed-loop control, signal processing, math calculations and PID regulators.

Engineers have the freedom to choose the I/O and commands for each module and set parameters like the spool position and current levels in an electronic valve, explained Liden. Then IQANdesign internally handles initiation and programming to create the logic that ultimately controls machine behavior.

In a traditional system, by contrast, a significant amount of development time is wasted just figuring out how to make components work together, he explained. Engineers on a conventional controls project may spend half the development time just solving integration problems so all the parts communicate with each other. That leaves less time to actually make the machine move and behave as desired. IQANdesign 5 cuts integration time by perhaps 80%, giving engineers much more time to optimize machine operation and behavior while completing projects faster. It makes for easy implementation of distributed machine control, said Liden.

Designers use the diagnostic section to specify data logging capabilities, methods for communicating with the cloud, and parameters for service technicians and operators to measure or display, he continued. It also defines machine security levels that apply to different users. Finally, the operator-interface display is completely configurable.

To further speed time-to-market, IQANsimulate software simulates the performance and interaction of all the hardware modules in an IQAN application in parallel with machine-function programming. This is a safer, quicker and more-economical way to test new applications versus building a physical prototype.

This virtual tool lets engineers generate inputs and measure the resulting outputs, view logs, identify errors, adjust parameters and test the operator interface—just like real components on an actual machine. “Because it is so user friendly, you don’t have to be a core programmer to do this. A skilled application engineer who understands hydraulics and the logic behind it can readily tune the system,” said Liden.

“IQAN lets engineers create not only efficient system layouts, but also the controls logic behind it,” noted Robert Lorance. “And that allows them to bring their products to market faster. You don’t need a massive IT organization to have a controls suite like this. It is very customer specific with a tremendous amount of flexibility to accommodate individual applications. We take care of all the tedious work, the diagnostics and all of the details so that our customers can focus on functionality—making the machine move and behave like the customer wants.”