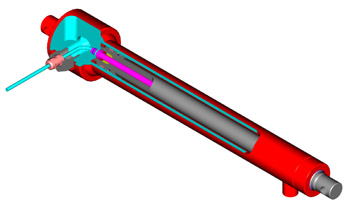

Rota Engineering’s model LA is the latest release of Hall Effect technology linear transducer designed specifically for the mobile hydraulic cylinder market. The LA was designed to have the smallest footprint possible so that the critical pin-to-pin dimension of existing cylinders would not be required to change.

Rota Engineering’s model LA is the latest release of Hall Effect technology linear transducer designed specifically for the mobile hydraulic cylinder market. The LA was designed to have the smallest footprint possible so that the critical pin-to-pin dimension of existing cylinders would not be required to change.

Rota Engineering is unique in the fact that they use Hall Effect sensors as one of their technologies for linear transducers, the other technology being reed switches for unique applications. The brains of the linear transducer are the microprocessor which controls and receives signals to the surface mounted Hall Effect chips, all of which are mounted on a PCB. The completed PCB with all the Hall Effect chips and microprocessor are then inserted into a stainless steel or aluminum housing depending upon the customer’s application. A magnet, which is supplied with every linear transducer, causes a voltage drop when it passes over the Hall Effect chip. The microprocessor understands the position of the Hall Effect chip and correlates the voltage drop to a proportional voltage, current, PWM or CANBUS outputs.

Rota Engineering designs and manufactures linear transducers for tough applications where robustness is required. Transducers can be designed up to 54-ft in length, for use 20,000 ft below the surface of the ocean, for hazardous environments and has voltage, current, PWM and CANBUS output options.