By J. Eric Freimuth • Hydraulic Training Associates

Hydraulics is all about the transmission of energy to perform work. As we discussed in our December article, accumulators store energy that can be used during power failure or when additional energy is needed. In certain situations, additional flow may be needed, so an accumulator can be used to supplement the flow rate of a pump. Unless dispensed of properly when working on a machine, anyone who manages to get in the way of the released energy could be injured or even killed.

Proper machine identifications and padlocks are crucial to lockout/tagout programs for machine maintenance. Image courtesy of IDEAL INDUSTRIES

Energy is not always obvious through your sense of hearing, smell, taste or sight; energy can elude all of our senses. To this end, lockout is a recognized systematic approach to controlling all forms of energy that may harm workers. The energy used in machines to perform work is relatively safe to personnel—as long as there are safeguards. At some point, personnel must interact with machines on an up-close and personal level, for such things as maintenance. It is at this time that uncontrolled energy becomes extremely hazardous to workers.

Understanding lockout while also being aware of the difficulties that can be found in the energy isolation and control of hydraulic systems is critical to safe machine operation and maintenance. Additionally, hydraulic energy can be an extremely difficult thing to isolate. The medium of a fluid under pressure is always seeking a way out of its confines. Crushing injuries are the most common injuries caused by exposure to hydraulic equipment where hydraulic fluid under pressure was not controlled and the mechanical component was not mechanically secured.

Lockout is a process of steps that are taken to safely control energy. Lockout is also about maintaining the security of having energy controlled over the duration of time. The thought that comes to mind is the padlock, which is only part of a much larger undertaking of sequences that is considered safe.

Machine manufacturers are required to integrate devices into their hydraulic system to allow the control, verification and isolation of energy at the design and manufacturing stages. Advances in laws and legislation have produced integration companies that specialize in conforming machines to meet machine safety regulations.

In many cases, testing and verification of hydraulic energy requires extremely precise measuring instruments. Much like multi-meters used for testing electricity, pressure testing equipment is used for hydraulic energy verification and is important in determining a “0 Energy State.” As little as a couple psi will generate extreme forces in a large bore actuator.

There have been numerous occasions where isolating devices have failed. Energy leakage through locked out isolation valves is possible. (The definition of isolation is the process of separating one thing from another; the purpose of isolating a hydraulic system is to protect one from hazardous energy sources.)

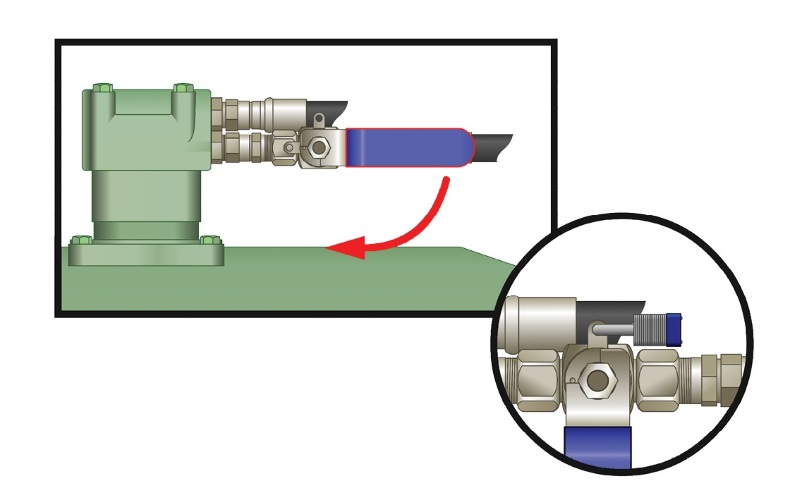

Methods such as lockable or monitored isolation valves are common ways to isolate hydraulic energy. This is most common in non-centralized hydraulic systems. Unlike centralized hydraulic systems, which are relatively easy to work on, doing work on a non-centralized system can consume a large amount of resources and time. Isolating a work area for a specific task is possible; however, it is critical that personnel are knowledgeable of the system and it is also critical that there are isolation devices integrated into the system. It must be known though, that energy will be present on one side of the isolation device using this method.

The accidental release of hydraulic fluid under pressure is most common in non-centralized systems. This is because there is a vast array of piping, tubing and interconnections in a non-centralized system. The accidental breach of interconnections containing hydraulic pressure is one of the highest leading causes of injury and environmental damage.

The accidental breach is usually caused by personnel:

• standing on a machine

• disconnecting a machine

• dropping large components on a machine

• connecting rigging for hoisting

• burning through and cutting through a machine

• completely removing fluid under pressure in a machine

The most common and favorable method of controlling hydraulic energy is to remove it completely. This is accomplished by the following:

1. shutting down the prime mover that drives the pumps

2. moving the actuators to a parked position

3. removing and supporting any overhanging loads

4. bleeding off all residual or trapped pressure

5. bleeding down accumulators

6. testing and verifying through specific procedures

All participants must have a clear understanding of the procedure for group lockout prior to the lockout commencement. Group lockout boxes should remain in the open position until ready, and be retained by the authorized individual to prevent the accidental locking of a lockout box prematurely.

It’s becoming common for companies to develop and post lockout procedures specific to individual equipment. Media such as placards, documentation and even training videos are used to train individuals in the duties required for an effective lockout. Step-by-step checklists are highly effective, not only for lockout, but also for the safe return of energy to the machine.

The procedures of a lockout program may contain the following elements:

• identification of the machine, its location and a description of what it does

• list of steps required for shutting the

machine down

• procedures in the shutdown process that

will assist in releasing loads and stresses in the mechanics, such as pinning and blocking, and release of hydraulic pressure through

the controls

• identification and location of energy isolation devices and their sequential use

• locations for lockout devices such as padlocks

Developing and educating all personnel and performing a rigid lockout/tagout procedure for all equipment will assist in saving lives and injuries. Neglecting to perform this procedure one time may mean the difference between injury and/or death.

Hydraulic Training Associates

htahydraulics.com