When it comes to bar stock, new product launches aren’t exactly an every-trade-show occurrence. Or even every couple for that matter. But if there is one manufacturing event suited to showing off a company’s shiny new toy, its IMTS. Which is why I was pleased to see Dura-Bar giving the industry a preview of a new product set for full scale availability just after the new year begins.

When it comes to bar stock, new product launches aren’t exactly an every-trade-show occurrence. Or even every couple for that matter. But if there is one manufacturing event suited to showing off a company’s shiny new toy, its IMTS. Which is why I was pleased to see Dura-Bar giving the industry a preview of a new product set for full scale availability just after the new year begins.

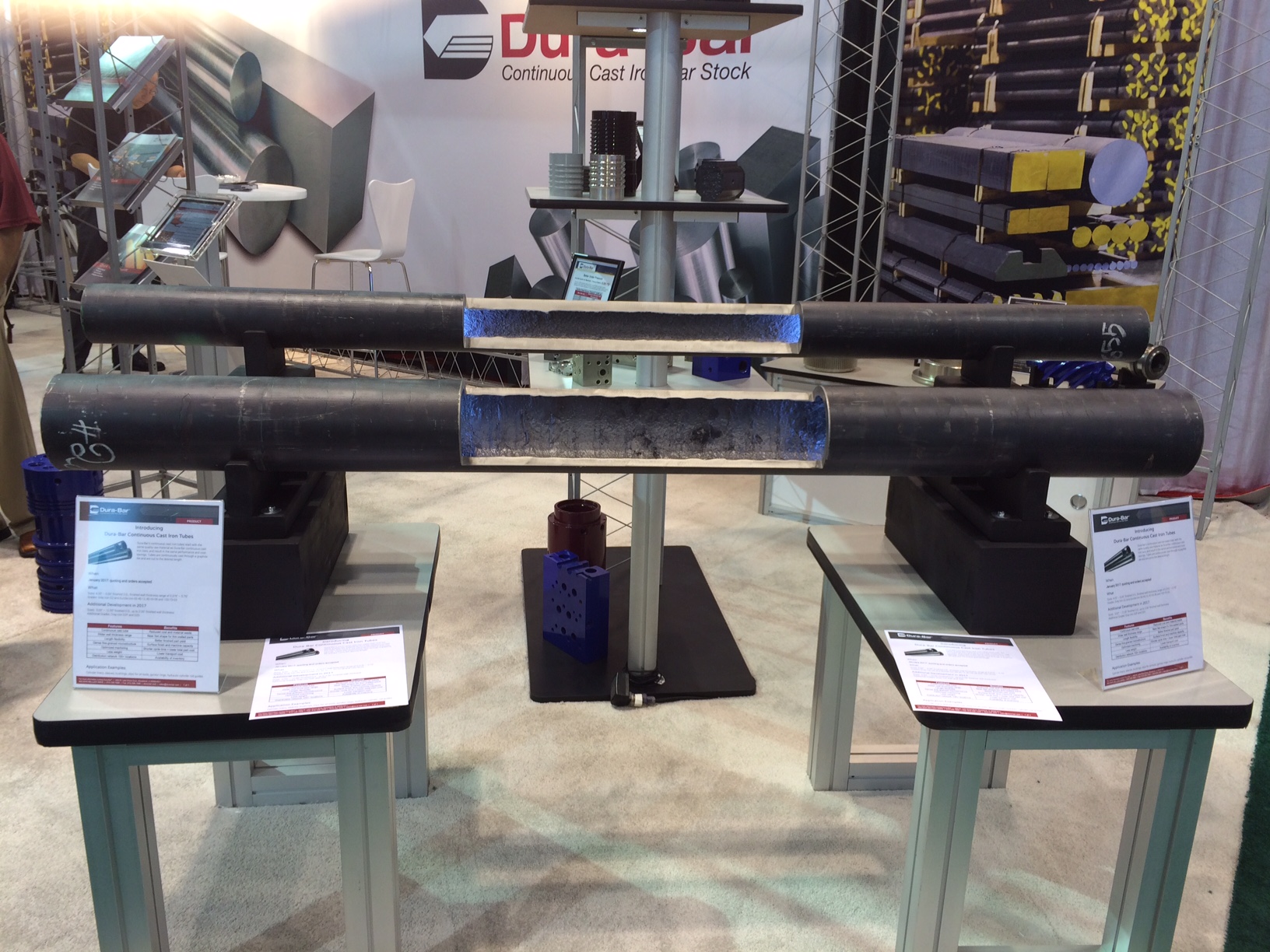

In the beta testing phase for the next few months, Dura-Bar’s new continuous cast iron tubes will be ready for quoting and accepting orders in January of 2017. The tubes are made from the same raw material as its continuous cast iron bar counterparts—and they maintain the same performance specs with reduced cost and material waste.

“The machinability of the material, in general, is going to be equal to that of our solid part product, which is typically 30-35% better than either a centrifugal cast or carbon steel,” said process optimization manager, Tim Heagney.

Additional features include length flexibility and a dense fine-grained microstructure for surface finish. The tubes are also continuously cast through a graphite die and are cut to the desired length. Sizes range from 4- to 6-in. finished O.D., with a wall thickness range from 0.375- to 0.75-in., with grades of Gray iron G2 and ductile iron 65-45-12, 80-55-06 and 100-70-03. The company says the tubes open doors for their product offering.

“The new continuous cast iron tubes will be free from typical sand casting conditions such as sand, hard spots and inclusions, which are detrimental to machining,” said product application engineering specialist Chris Heczko.

Krista Billert, marketing manager, added, “It gives us the ability to create a product in sizes that we typically can’t with our current solid material product.”

And that’s just what’s new for early 2017. Dura-Bar officials say that later in the year, the company expects to expand available sizes to include 3- to 12-in. finished O.D. tubes with up to 2-in. finished wall thickiness and additional Gray iron G2P and G2S grades. Application examples include cylinder liners, sleeves, bushings, slips for oil tools, gyrotor rings, hydrualic cylinder rod guides and others.