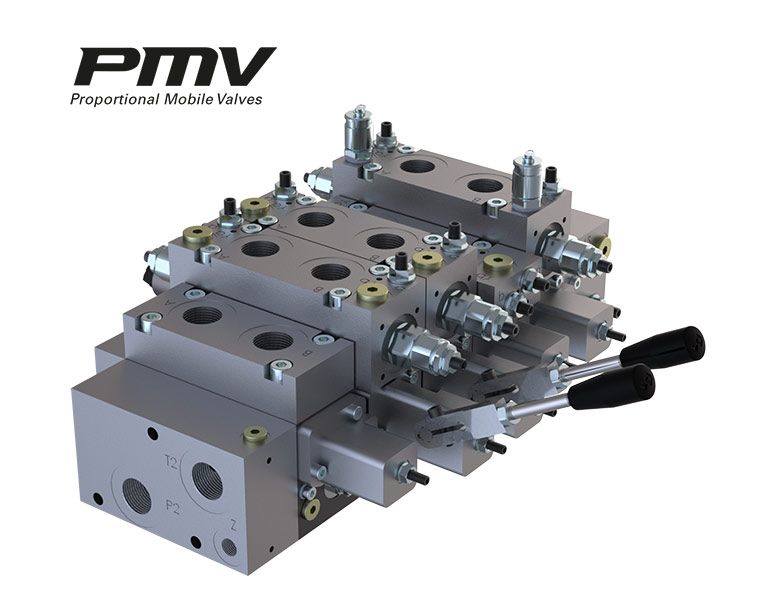

One of my final stops at IFPE 2023 was a briefing with Gary Gotting, President & CEO, Wandfluh of America Inc., particularly about their newModifications, to and between them, can also be carried out quickly in the field. Due to the modular design, special solutions can also be created in a flexible manner. For example, counterbalance valves integrated in the connection plate or operated non-return valves can be integrated. By means of the 2-way pressure compensator, the flow can be controlled independent from the load.

PMV valves are used where compact installation dimensions are required and a function requires sensitive control. Typical applications are cylinder and motor controls for all handling functions as in loading cranes, telescopic handlers, aerial platforms, municipal vehicles, construction machinery, drilling equipment, agricultural and forestry machinery, offshore applications, underground mining.

Gotting noted that the PMV allows for very precise flow control in either direction, either electrically or manually controlled. The model on display showed how you can easily mix two different sizes of valves — a very large and small one, with a controller — and power beyond feature.

“This is basically a brand new package that has a very, very good pressure compensator, so our pressure compensation throughout is flat throughout,” Gotting noted. “It’s targeting machines where we typically have large flow.”

Gotting said that the pressure compensator is extremely linear. While operating the PMV over the entire flow range, you’ll find that it’s providing the exact flow regardless of the load. Wandfluh can offer pre-imposed compensation, which can be added even after you buy the valve. With sectional valves, pre-imposed compensation must be ordered and built into it. Wandfluh can add it as an option later.

“So if you buy it and you find you need it, you can have that cost of putting it on later,” Gotting said. “You’re not stuck with something you either don’t need or you’re not stuck without something that you do need.”

“Future accessories can easily be fit into the ports. The outlet ports allow you to have

electrically operated valves to lock something in place or your driver, you can lock it into place,” Gotting said. There’s a lot of other accessories as well, like the power beyond which allows you to use the ports on the end to build another small manifold block to do some auxiliary features around this.”

It can be electrically and mechanically operated and features mechanical stops, to limit the flow mechanically.

Pressure return ports on both ends allow you to feed the valve from both sides, said Gotting. But the PMV also features pressure and return in the middle as well, which allows, for instance, you to run one half of the valve at 210 bar and the half of the valve at 350 bar. “So we’re not wasting energy by, by driving high pressure and having to reduce it,” Gotting said.

Gotting said the modularity allows users to buy exactly what they need. The fully Wandfluh valve comes with 10 million operations and all the other features that Wandfluh offers. Additional accessories and end plates will grow with user needs.

All the published curves in the data sheets come from large, real samples, and 100% of the products are factory tested, so are guaranteed to work. The PMV has been designed specifically to be extremely flexible, to fit all those various market segments that Wandfluh serves.

Gotting said this type of functionality, productivity and flexibility has allowed Wandfluh of America to grow 38% as a company last year. “We haven’t gone for the weird and wacky application stuff. We’ve gone for the easiest way to give them the standard stuff. And as with everything else we do, the moment you plug something of ours into an existing hole, there’s, there’s an uplift in the performance of the of the product.

“There’s an immediate change for the operator and a comfort level that comes knowing that between our valve, you have something like a 0.4 and 0.5% difference between valve to valve,” he continued. “So when you start using our product in a series like these, they’re all very tightly toleranced. You don’t have to keep adjusting everything every time and the operator is moving from machine to machine, it feels the same to you.”

Wandfluh offers delivery of 4 to 8 weeks maximum on anything in its catalog, including the new PMV valve.

Wandfluh of America

www.wandfluh.com