HMA Fire, based in Fall River, Wisc., develops fire-fighting equipment and systems for a range of on- and off-road vehicles — from custom mini-pumpers and skid units for ATVs to add-on packages for full-size fire vehicles. Its goal is to make fighting fires safer and more efficient by using ultra-high pressure (UHP) technology. The company recently teamed up with Kraft Fluid Systems, Strongsville, Ohio, to develop a compact unit that’s hydraulically powered.

Ultra-high pressure is defined by the National Fire Protection Agency as pump pressures above 1,100 psi. Spraying water at these pressures breaks down conventional water droplets into scores of smaller particles which, in turn, increases the total droplet surface area ten-fold. Greater surface area means more contact with the fire and more efficient heat absorption. When a water droplet absorbs heat it converts to steam which, in turn, displaces oxygen, cools the superheated environment and extinguishes the fire.

Tests show that UHP can put out fires in about half the time and using only one-fifth the water, compared to conventional systems that supply water at around 125 psi. This makes vehicles equipped with HMA technology viable, effective alternatives to traditional firefighter pumper trucks.

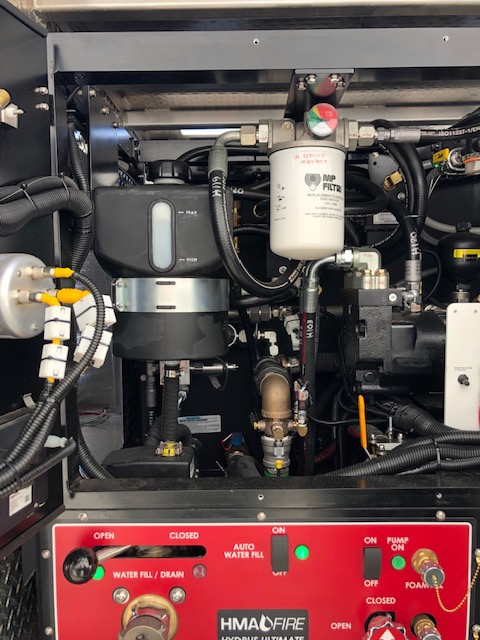

Recently, the engineering team at Kraft was asked to help HMA design a hydraulic system for a Ford F550 truck that would power two 20 gpm water hand lines while not overloading the PTO (pilot take off) under any conditions. And it had to fit within the very limited space available on the F550 platform. In addition to the UHP drive system, Kraft also had to design a second circuit to supply low-pressure water to the inlet of the UHP pump.

To meet hydraulic power requirements, the Kraft experts selected a compact Danfoss H1P 53 cc pump. The variable-displacement, axial-piston pump is noted for high-power density and excellent efficiency, along with a durable, robust design that’s suited for demanding working conditions. The pump uses electric displacement control along with a built-in speed sensor to ensure precise output. It’s rated for working pressures up to 380 bar (5,511 psi).

A fixed-displacement Danfoss series 90, 75 cc axial-piston motor was selected to drive the UHP’s triplex water pump. Information from a transducer that reads the water pressure on the UHP system, along with data from the speed sensor on the Danfoss pump, is transmitted to a Danfoss mobile electronic controller that monitors and regulates the H1P pump’s displacement.

As a result, the system maintains maximum torque on the H1P drive pump. Whether one hose line is used, or both, the closed-loop control will back off the pump displacement or increase it in order to maintain the programmed maximum system torque, thanks to the compact and efficient hydraulic system that powers the UHP firefighting equipment.

“We know ultra-high pressure,” said Greg Filut, HMA Fire’s production manager. “Kraft Fluid Systems knows fluid power hydraulics and control. The experts at Kraft were instrumental in helping us design from the concept stage all the way through run-off of this very important vehicle for our company.”

Kraft Fluid Systems

www.kraftfluid.com