Controlling the tire pressure of crop harvesters has numerous advantages, due to different vehicle handling characteristics whether operating on roads or in fields. To address the need, Bosch Rexroth introduced the GFT 8150 TIS (Tire Inflation System), which enables dynamically optimized tire pressure in machines, at Agritechnica 2019 in Hannover, Germany.

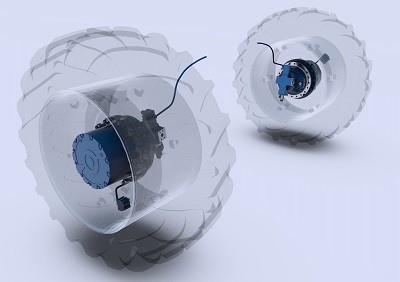

The new GFT 8150 TIS travel drive is reportedly the first fully integrated tire pressure control solution for harvesters with individual-wheel drive. The system is seamlessly integrated into the machine and operates via a standard terminal in the cab. The GFT 8150 TIS uses a compact travel drive from Rexroth’s GFT 8000 series powered by the company’s A6VE high-pressure hydraulic motors.

The Tire Inflation System controls pressure through the planetary gearbox and takes up no additional vehicle space. Previously, tire pressure regulation could only be carried out by retrofitting the vehicle frame with cumbersome external piping that is susceptible impacts and damage.

For users, the TIS can improve efficiency and driving stability at the same time. In fields, operators can lower tire pressure and expand the contact surface area, thus reducing ground pressure, increasing traction and limiting slippage. For transit, pressure in the tires can be raised to improve vehicle stability on the road, reducing tire wear and fuel consumption.

The hydrostatic compact drive consists of a two-stage planetary gearbox in combination with a hydraulic axial-piston motor. The GFT Series 8000 compact drive for heavy-duty vehicles is a complete transmission unit, which is characterized by its simple installation according to Rexroth officials.

It features a robust design for use in temperatures between -25° and 40° C (-13° to 104° F), and it is built to handle environmental extremes such as sand, dust, severe shock loads and aggressive media. It is also available with a dynamic brake. The brake is housed inside the gearbox, protected against grime and the weather, which contributes to the compactness of the entire transmission unit and, at the same time, results in low-maintenance operation.

The mechanical section mates with compatible Rexroth A6VE bent-axis hydraulic motors. Several motor sizes are available with displacements from 115 to 170 cc. Nominal motor operating pressure is 450 bar with a maximum rating of 500 bar (6,527 to 7,252 psi).

They feature space-saving construction due to a recessed mounting flange, and they simply slide into the mechanical gearbox for easy installation. The motors have a high starting efficiency, excellent slow-running characteristics, wide control range (can be swiveled to zero), provide high torque and are approved for high-speed operation.

In addition to the functional benefits resulting from optimal matching of the mechanical gearbox with the hydraulic motor, the product also offers advantages in terms of logistics. The availability of a complete transmission unit simplifies procurement processes, and the modular and flexible design means virtually off-the-shelf availability and short delivery periods.

The complete GFT 8150 TIS unit serves mainly as a drive component for wheel-driven harvesters with single-wheel drive, such as corn or potato harvesters.

Bosch Rexroth

www.boschrexroth.com