By Josh Cosford, Contributing Editor

We live in a global village where local preferences seem to matter less, and acceptance of unfamiliar ideas more widespread than ever. Thirty years ago, the idea of metric bolts, nuts, threads or other objects measured in round numbers was cringe-worthy, especially in the manufacturing space. Many found it annoying that their ½ in. open wrench kept stripping the 12 mm bolt head on their Honda Civic.

We’ve come a long way in the automotive realm, and now most fasteners in nearly every vehicle sold in North America are metric. By now, most technicians and backyard mechanics own a full complement of metric hand tools. However, even with those tools readily available, how far have we come in the hydraulic realm with accepting metric?

We’ve come a long way in the automotive realm, and now most fasteners in nearly every vehicle sold in North America are metric. By now, most technicians and backyard mechanics own a full complement of metric hand tools. However, even with those tools readily available, how far have we come in the hydraulic realm with accepting metric?

As far as plumbing goes, I can tell you the metric adaption has been slow at best. We still prefer our inch dimensions here in North America, so very few ports, fittings and adaptors are specified as metric unless on a machine from overseas. So what about hydraulic cylinders … have we transitioned into any practical standard?

In a word, no. We crave familiarity, and although you find more metric cylinders than you do metric plumbing, they’re usually only sold here as replacements. In fact, you’re more likely to offer your customer a “soft-crossover” of their metric cylinder.

A soft cross refers to replacing a metric cylinder using an inch-dimensioned version by local repair or manufacturing shops. This practice is actually quite common and involves using off-the-shelf rods, barrels and seals from readily available North American material. There is no bias against metric, but many forms of raw material are simply not available locally in metric dimensions.

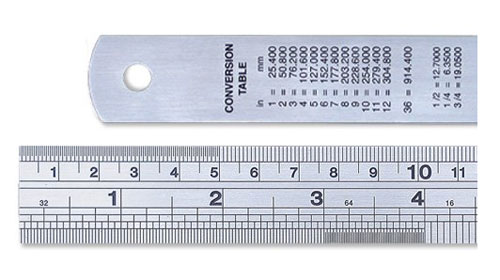

For example, your customer’s 80 mm bore cylinder with M33x2 rod thread dropped off at your back door may still be repaired or replaced, even without a source of metric raw material. Many metric cylinder sizes find themselves closely related to their inch counterparts, and this 80 mm bore cylinder may be replaced with 3-1/4 in. As far as the 33 mm thread is concerned – any machinist worth their salt can machine any thread, so the form is not difficult to match.

The primary challenge with a cylinder soft crossover is the mounting. NFPA mounts are very similar to ISO 6020/2 and DIN 24 554 cylinders, except for a few mounts and numbers round off for simplicity. However, a custom head, cap or another component must likely be manufactured to fit the original cylinder’s mounting dimensions. Alternatively, the metric cylinder’s mount may be nothing like any North American standard and requires custom manufactured parts.

Either way you spin it, your customer will have two options – the expensive custom replacement made quickly or the factory cylinder likely shipping from overseas and taking weeks. Nearly every customer claims their cylinder repair is urgent until you provide the “urgent price.” Honest customers will pay anything to get up and running, so often times your expensive soft crossover doesn’t phase them.