HydraForce will showcase innovative electrohydraulic control solutions for the construction and mining industries in Hall A4 Booth #425 at Bauma Munich, April 15-21, 2013.

Protecting equipment from corrosion is a HydraForce initiative with the launch of corrosion-resistant coatings for standard, as well as high-pressure-rated cartridge valves. The zinc-nickel plating withstands 1,000 hours of salt spray prior to rusting and meets the ASTM B117 standard for corrosion-resistance. More than 2,000 models of solenoid, directional, flow and pressure control cartridge valves can be ordered with the corrosion-resistant coating. All HydraForce environmental solenoid valve coils (E-coils) are also protected with corrosion-resistant coatings, at no extra charge to the customer.

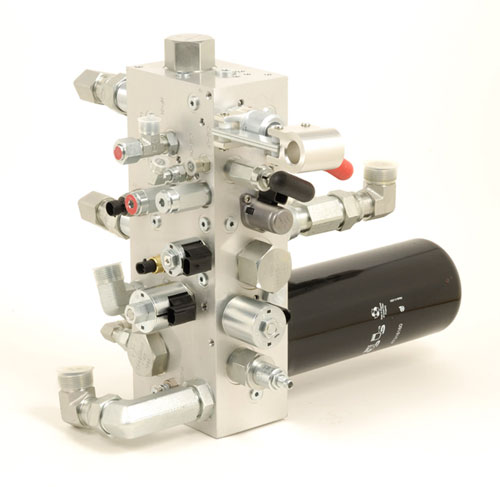

Multi-function cartridge valves that reduce hydraulic “footprint” by incorporating two or more functions, such as load-sensing, load-holding, directional and flow control, and pre- and post-compensation of hydraulic flow into a single valve. Models HSPEC (a proportional solenoid with built-in compensator) and SPCL (proportional solenoid with integral load-sense and check valve) are two examples of cartridge valves with multi-function capability.

On the electronics front, HydraForce offers a CE-qualified EVDR-0201 two output valve controller, which is ideal for electrohydraulic attachments and other applications that need an additional output.

PED-compliant pressure relief valves, HyPerformance™ high-pressure cartridge valves and numerous system solutions will also be on display at the HydraForce booth.

HydraForce’s display at Bauma Munich will be staffed by fluid power engineers with the expertise to field technical questions and provide innovative ideas for the construction and mining machinery markets.

HydraForce

www.hydraforce.com