By Josh Cosford, Contributing Editor

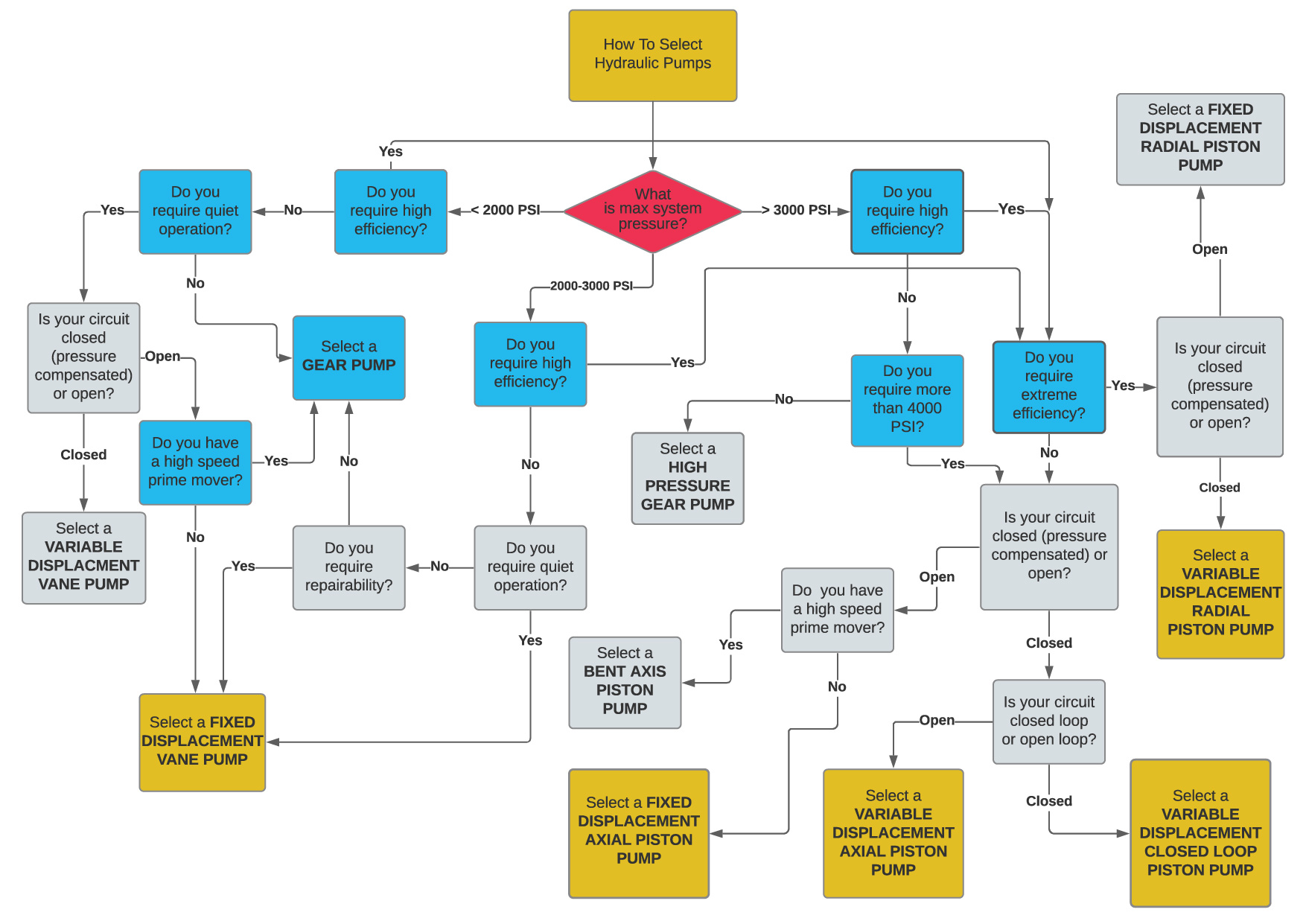

Hydraulic pumps convert mechanical energy into hydraulic energy, and it goes without saying every hydraulic system requires such a device to transmit controlled force to the actuators of your hydraulic machine. How you select a pump comes down to many factors but working through this guide will help you select the best pump for your system’s needs.

Piston, vane and gear pumps are the main designs used in hydraulic systems, and understanding that fixed-flow applications use gear and vane pumps will help in your decision, while axial-piston pumps are suited to variable-displacement needs.

You should consider such factors as maximum system pressure, efficiency requirements, speed requirements, closed or open circuits, and noise control. The flow chart below will help you arrive at the correct pump design and style for your application.

This is obviously just a start to selecting a hydraulic pump for your application, but once you have arrived at a specific type, you can further hone in on specific needs. For more on pump styles and selection, read more about fixed versus variable designs, pump symbology, and positive-displacement pumps here.