Flow-on-Demand systems enable energy-saving mobile drive technology.

By Dierk Peitsmeyer, Product Portfolio Manager, Bucher Hydraulics, Klettgau, Germany

The Paris Agreement is the landmark environmental accord that aims to address the negative impacts of climate change and substantially reduce global greenhouse gas emissions. Although the U.S. will formally withdraw from the Agreement on Nov. 4, nearly 200 countries have signed on, and many American city and state government officials, scientists and businesses leaders, researchers and academics continue working toward the goals of the accord.

Likewise, countries around the world are driving clean-energy advances to mitigate climate change. For example, the E.U., with the “Green Label” initiative and the German government with the “Energy Efficiency Strategy 2050,” have politically stipulated that CO2 emissions must be significantly reduced.

These provisions will have a major impact on technical developments in the next few years, and the changes will most-assuredly affect manufacturers and users of construction, agricultural, mining and forestry equipment. Already, highly efficient drive systems, alternative powerplants and hybrid drives are increasingly used. Future mobile machines will likely be equipped with battery-powered electric drives, fuel cells, or diesel generators. To adapt to this changing landscape, hydraulic systems will require more efficient components and systems for precision movements.

Drive-technology challenges

Many major mobile-equipment manufacturers, and their drive-system suppliers, are investigating alternatives to conventional IC-powered machines. A number of OEMs have developed battery-powered prototypes, and some have introduced commercial products.

But there are challenges when adopting new drive technologies. For operators to work economically, electrically driven mobile machines must fulfill some important criteria. The designs will need to achieve sufficiently long operating times without tedious recharging and to work reliably and quickly at high power levels, similar to current machines. Operating companies also demand low noise emissions and low costs in terms of energy consumption and maintenance.

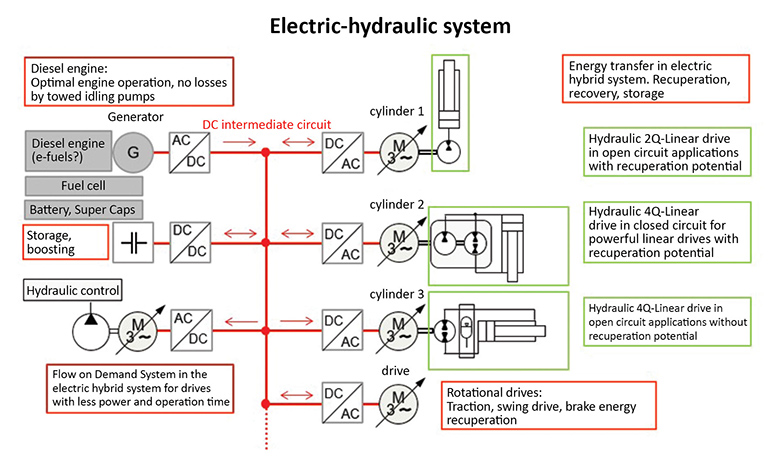

The circuit powers individual electric motor-pump combinations to supply working actuators. Energy transfer in the electric hybrid system enables recuperation, recovery and storage. Likewise, it powers rotational drives for traction, swing drives and brake energy recuperation. Flow-on-Demand systems are for drives that demand less power and shorter operating cycles.

Higher efficiency will be a primary factor in the success of the new designs. Lengthy operating time can be achieved with large batteries or other energy sources. However, this results in high expenses for the components. Systems with low power dissipation using efficient components or systems can prove to be useful, as they reduce the need for cost-intensive energy.

Electric drives already have a high efficiency over a wide operating range. On the other hand, the hydraulics used today in mobile machines powered by diesel engines are not efficient enough. Improved systems need to be installed.

Limits of existing hydraulics

Hydraulic systems that adapt to the current volume and pressure requirements with the aid of variable-displacement pumps, so-called load-sensing systems (LS systems), are not optimal for electrified machines. The noise emissions of conventional variable-displacement axial piston pumps are too high. They will be particularly prominent in electrified machines due to the absence of diesel engine noise.

Another problem is that the level of efficiency of LS systems is not optimal throughout the entire operating range. Load-sensing systems adapt their pressure to just above that of the highest load. A pressure difference, typically around 20 to 30 bar (290 to 435 psi) between pump and load, is necessary to overcome losses in hose, connectors and valves.

These losses are system dependent and will change with external conditions such as temperature (for instance, poor cold-start performance), oil properties, and hose and tubing lengths. Thus, the pressure margin must be set to worst-case conditions to handle all operating demands. The control deviation causes unnecessary losses at most operating points.

Another weakness of load-sensing systems is possible stability issues. The pump in an LS system is controlled in a closed-loop mode. At certain points of operation, this might result in an oscillatory behavior. Significant damping is occasionally necessary to operate the LS system without oscillation. This extends the response time considerably.

Consequently, it is not advantageous to replace the diesel engine with an electric motor and leave the existing hydraulic system unchanged.

Inadequate electromechanics

Some researchers have looked at minimizing the use of hydraulics, for example, replacing hydraulic cylinders with electromechanical linear drives. But in nearly all cases it has proven to be impractical. Mechanical gearboxes are not suitable for the high loads of a construction machine. Furthermore, every electromechanical linear drive requires an electric motor with correspondingly high power. The installed power will be quite high in total, even though it is rarely or never needed all at the same time.

As a favorable compromise between high efficiency and low cost, an optimized hydraulic system can be used. Closed-circuit displacement controls are an excellent choice for high-performance functions with a high potential for energy recovery. These are the ones with the lowest energy losses.

One proposed solution for high-efficiency mobile hydraulics is shown in the accompanying “Electric-Hydraulic System” graphic. Here, each linear function requires a combination of electric motor and pump, comparable to electromechanical linear drives. Active control of the motor’s rotational speed precisely meters flow to the actuator. And in these circuits, the pump is typically smaller and sized to the specific actuator, versus a pump that must supply maximum flow to numerous cylinders.

Electric motor/pump applications means closed-loop motor control for each cylinder. It provides for the highest energy efficiency and regeneration, such as from crane or excavator booms. Such systems are not yet common in commercial mobile machines, although somewhat similar concepts are used in aerospace applications. But is an expensive solution, which does not make sense for every work function.

Flow-on-Demand hydraulics

For precision movements, valve controls with “Flow on Demand” (FoD) are an economical alternative. FoD applies one e-motor and one pump for several cylinders, consequently for lower costs. This makes sense for work functions that require less power, shorter operation times and without regeneration potential.

The idea behind Flow on Demand is to use operator joystick signals to control the pump flow and valve openings simultaneously. The pump displacement setting is controlled according to the requested load flows. Compared to traditional load sensing, the function does not need a pressure-control margin (Δp).

Pump pressure is always at the lowest possible level needed to satisfy the load and overcome line flow resistance inherent to any system. When an actuator is stationary, the pump destrokes and delivers no flow and the directional valves close. Activating a joystick will simultaneously open a valve and increase the displacement of the pump.

Because pump pressure will adapt itself to a level needed by the system, Flow-on-Demand systems can be significantly more energy efficient compared to load-sensing systems. The pressure difference between pump and load is given by the system resistance, rather than by a prescribed pump pressure margin.

Advanced controls

Several elements are key to a successful FoD system. Hydraulic control blocks with separate control edges, such as the LVS12 valve from Bucher Hydraulics, reduce power loss and enable movements to be more dynamic; therefore, the effectiveness of the machine is further increased.

The LVS12 is a proportional valve with integrated pressure sensors and flow-sharing compensators. The valve uses split spools that allow for independent activation of the control edges that govern metering in/out. FoD and the meter-in edge only control cylinder speed; the meter-out edge controls generative loads, such as for lowering and braking.

It is possible to combine variants of electric drives and hydraulic systems optimally in machines with a dc intermediate circuit. For example, the hydraulic pump can be operated as a fixed-displacement, variable speed pump. The speed of the electric motor must be set accordingly.

As mentioned previously, in FoD systems the operator’s joystick signals control the pump flow and valve opening simultaneously. For this to work properly, the system software needs knowledge about every flow consumer. That, in turn, requires sophisticated control algorithms.

Bucher Hydraulics’ FoD software makes this possible without additional effort for the hydraulics user. The system calculates the required optimum speed based on the valve actuation characteristics. The result of the FoD system is always the lowest possible pressure at the pump. It depends on the current load and pressure losses, the latter which can be minimized by optimizing system design. It is particularly advantageous that the control pressure difference required in LS systems is eliminated.

As a result, the responding behavior is extremely fast and direct, comparable to the performance of electric travel drives. The control system works in a stable fashion without oscillations. This allows the operator to drive the machine more effectively. The FoD system also offers additional advantages for controlled functions, such as the assistance control systems. And Bucher Hydraulics’ FoD software features additional options that are not available with a traditional LS system.

Pump efficiency is crucial

In variable-speed operation, the pump is of particular importance to meet the special requirements of an FoD system and closed-circuit controls. The pump is the heart of the system. Comparable to the efficiency of high-quality electric motors, it must run at 92 to 94% efficiency over a wide operating range. This minimizes the need for costly battery capacity and extends the achievable service life. Reducing power dissipations at the hydraulic pump, for example, from 5 to only 2.5 kW, contributes significantly to the energy-efficient operation of the machines.

The efficiency chain further enhances this effect. The AX series hydraulic pumps from Bucher Hydraulics are especially suitable for such drive combinations. Even during demanding high-performance operation, the noise level is low and pleasant, as expected by end users. The pumps can be started at high pressure and operated at very low speed — only a few rpm —without premature and excessive wear. Due to low leakage and the high number of pistons (24 versus 7 or 9 in a typical axial piston pump), smooth cylinder movement can be achieved even at low speeds. This is particularly beneficial for positioning work and large booms. The design principle with consistent hydrostatic relief of the components makes these pumps particularly reliable. (For additional information on AX pumps, see www.mobilehydraulictips.com/new-design-overcomes-piston-pump-limitations.)

With AX pumps and FoD software, as well as closed-circuit linear drives, the hydraulic systems of Bucher Hydraulics perfectly meet the requirements of electrified machines. Currently, such systems are in the early stages of beta projects for truck-mounted applications, construction machines and material handlers.

Bucher Hydraulics

bucherhydraulics.com