Offering precise control with high flow and small deadband, Eaton’s new ESV9 series of proportional solenoid cartridge valves are designed to provide superior control with optimized linearity. With less than 7% hysteresis, the new valves provide excellent operational efficiency and a broad ramp rate for greater resolution and ease of use.

Offering precise control with high flow and small deadband, Eaton’s new ESV9 series of proportional solenoid cartridge valves are designed to provide superior control with optimized linearity. With less than 7% hysteresis, the new valves provide excellent operational efficiency and a broad ramp rate for greater resolution and ease of use.

“The new ESV9 offers the highest maximum flow in its class without sacrificing on efficiency or control,” said Todd McIntyre, product manager, Global Planning and Strategy, Eaton’s Hydraulics Group.

It features a low deadband as it begins to open because of the dual spring design it uses. Using a combination of one light spring and one heavier spring results in lower hysteresis through the tolerances and finishes in the product.

McIntyre continued, “The ESV9 spool is more highly controlled than single spring designs. This results in lower hysteresis, higher maximum flow solving many of the challenges engineers face in applying proportional control to many construction, agricultural and material handling vehicles.”

Maurice Ashmore, Chief Engineer Cartridge Valves for Eaton, added, “The hysteresis is certainly a lot better than the competition. The competition brought these out really quickly and I don’t think they developed it onto the next stage which is what we tried to do.”

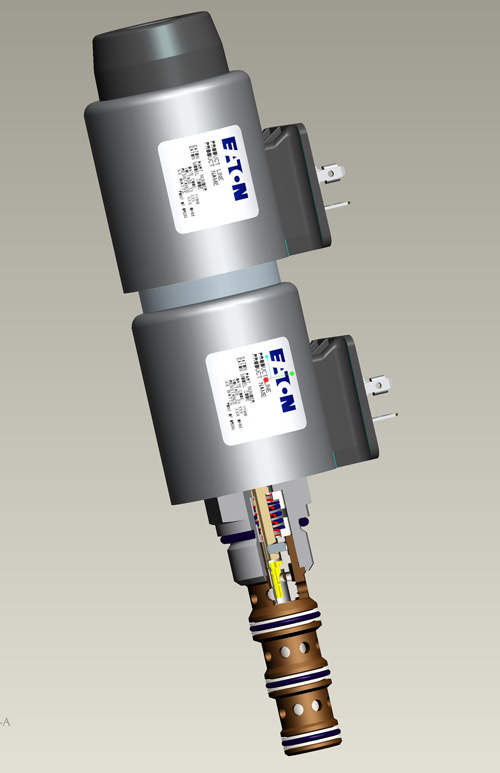

The size 10 ESV9 is a four-way, three-position screw-in cartridge and is available with either a closed or float spool configuration. The E-spool type solenoid valve has all the ports closed in the de-energized position. This configuration is ideal for moderate flow applications where an actuator needs to be proportionally controlled in both directions and stopped in any position. The float or motor spool in the de-energized condition features ports two and four open to tank with the inlet port three blocked. This allows the service ports to decay to tank pressure in the de-energised condition. The ESV9 has a rating of up to 22 lpm and up to 250 bar, matching the technical requirements of most applications.

As an option, the valves are available with a manual override and additionally can be fitted with or without the IP69K compatible “L Series” Large ToughCoils. The valves are available in 12 or 24 V direct current coil voltages, with or without a diode, along with a number of housing materials (steel or aluminum) and port sizes.

Ashmore added that by combining the ESV9 with compensators, Eaton can now produce meter-out, compensated versions that function similar to its CLS range of valves when it comes to flow sharing. The CLS load-sense sectional mobile valve allows work functions to be prioritized to improve performance and efficiency. If offers priority flow sharing and local load-sense relief on each section.

In mobile construction, agriculture and material handling applications, the valve can be used in place of Eaton’s industrial-rated, high-flow KDG4-V3 valve series, providing a more cost-effective, general-purpose solution. The ESV9 valves are also smaller, reducing the manifold size and cost. They also allow increased flexibility during installation.

The compact design can fit into both size 8 and 10 common cavities, particularly for compact machines like small cherry-pickers and lifts with baskets, said Ashmore. “They have very little space and so this is really a boon for them, where they can’t fit a big valve in, and when they want flow sharing, it can come very expensive.”

Eaton

www.eaton.com/hydraulics