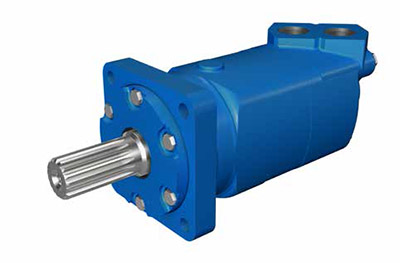

Eaton has announced the advancement of its Xcel Series portfolio of low-speed, high-torque motors with the availability of the XL4 and XL6 options.

Featuring Eaton’s reliable Geroler design, the new XL4 and XL6 motor options expand available torque ratings for the Xcel Series up to 16,800 in.-lbs [1898 Nm] and include an internal three-zone architecture for high, low and case pressure. This results in less wasted energy and lower operating temperatures, giving machine designers the durability their application needs at a price point the machine can support.

“Competitive motors are often designed with two zones and no case drain,” said Mandee Liberty, product manager, Geroler Motors, Hydraulics Group, Eaton. “This makes them vulnerable to motor damage and premature failure. The three-zone architecture of Eaton’s Xcel motors dampens pressure spikes in both directions, extends shaft seal life and enhances overall reliability.”

Many applications require a mix of motors for different performance and functions. Eaton’s Xcel Series of low-speed, high-torque motors are designed for systems with medium-duty cycles such as salt and sand spinners, street cleaner brushes, combine reel drives and stake-down motors.

Xcel Series low-speed, high-torque spool and disc valve motors also offer the most popular options for shafts, ports, mounts and displacements to simplify and shorten the design process.

This new offering fully rounds out Eaton’s Xcel portfolio of Gerotor/Geroler motors, delivering performance, value and reliability in a broad range of applications.

Eaton

eaton.com/Xcelmotors