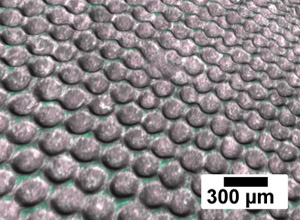

Friction between lubricated surfaces is a principal source of energy losses in fluid power systems—a ubiquitous problem for fluid power users across the industrial spectrum. But thanks to research underway within the Engineering Research Center for Compact and Efficient Fluid Power (CCEFP), that problem is on its way to resolution. Led by Professor William King, researchers at the University of Illinois at Urbana-Champaign are developing low-cost, microstructured surfaces having a significantly reduced coefficient of friction compared to surfaces with a conventional surface finish.

“This research allows us to design and then manufacture microstructures onto a surface that will dramatically reduce the coefficient of friction,” said William King, who is the College of Engineering Bliss Professor at the University of Illinois.

It has long been known that when rough surfaces slide against each other, the roughness causes reduced friction. The reduced friction arises from hydrodynamic effects caused by the roughness. Before now, it was not possible to harness this effect for industrial applications.

“We have combined two new technologies” says King. “First, we have created a computational design tool that lets us start with the application parameters—machine speed, lubricant type, and so on—and choose the optimal microstructures. Second, we have developed a low-cost manufacturing technique to put these microstructures onto machine components.”

Using techniques they developed, Dr. King and his team have fabricated these patterns on large surfaces of different shapes including curved surfaces. This technique has been extended to many metals including stainless steel, cast iron, nickel alloys, and tool steels.

Professor King and his team are interested in working with companies who may have applications in mind for their research findings. For further information, see www.ccefp.org, project 1D (Micro-and Nano-Texturing for Low-Friction Fluid Power Systems), or e-mail Dr. Stelson, CCEFP Director or Dr. King.