I wrote about the ISO 4406 cleanliness code in my last two blogs here and here, and today I’d like to take it a bit further and discuss beta ratios. Beta ratios are important to help us identify the quality of a hydraulic filter element. If using the ISO Code to help identify and specify […]

Hydraulic Fluids

Why the ISO code matters

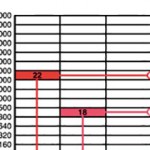

Earlier this month, I explained the meaning behind the ISO 4406 contamination code, so now I’m explaining why it matters, and how you can apply it to your application. The code describes the quantity of 4-, 6- and 14 -μm particles in a milliliter of hydraulic fluid—because these particle sizes are considered the most damaging […]

Understanding ISO 4406

The most critical quality of hydraulic fluid you should consider is that of cleanliness. We refer to the size and quantity of particle contamination when discussing cleanliness, and so that we are all on the same page, standards were created for measuring and expressing this quality. Although the standard for oil cleanliness has changed over […]

Freudenberg-NOK forms new ARPM seals committee

There are two industry challenges a new Association for Rubber Products Manufacturers (ARPM) committee being launched by Freudenberg-NOK Sealing Technologies will likely tackle in the future. This new working group will focus on the evolving technical needs of seals and gaskets manufacturers throughout the world, said Joseph Walker, global director, Advanced Materials Development for Freudenberg-NOK. […]

The challenges of mobile reservoir design

Hydraulic oil spends most of its time in the reservoir, and as such, various tank design criteria provide benefits for the hydraulic system as a whole. When designing the optimum hydraulic reservoir, most of the considerations are in keeping the oil clean and cool. Reservoirs in industrial applications are spoiled by the extra space and […]

Conserving energy and reducing leakage with hydraulic fluids

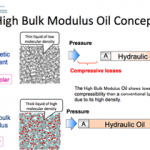

Leakage and system efficiency are always at the top of fluid power users’ minds. This is why several CCEFP researchers are focusing on how to optimize system sealing and fluids at the Center’s second annual Fluid Power Innovation & Research Conference 14 at the Marriott at Vanderbilt University in Nashville. Kicking off a track on […]

5 things your father never told you about mobile hydraulic fluids

Josh Cosford • Contributing Editor Dad was a lot of things, but he was no hydraulic expert. However, that doesn’t mean he (and everyone else) didn’t have an opinion on hydraulic oil. The problem with opinions is that they come from persons with enough knowledge that people listen—but enough knowledge to be potentially dangerous with […]

Hydraulic fluid contamination: The greatest danger to your system

David Marlowe • Owner/CEO • DMAR Technical Training and DMAR Business Centers When conducting a class on hydraulic and lube oil systems, I often find that the students are surprised by how much fluid condition affects system operation and the numerous mechanical problems that derive from the oils not performing at 100% of design characteristics. […]

World’s most powerful test bench for hydraulic seals helps qualify A350 main landing gear

To test seals for critical applications, Trelleborg Sealing Solutions invested in one of the world’s most powerful test benches for hydraulic rod seals. This facility allows testing to be carried out that has never been possible and has been used to qualify the seals for the landing gear of the Airbus A350. The sealing system […]

Sensor Monitoring Unit – SMU and New Version of TPM

Schroeder Industries, recognized in filtration and fluid conditioning products, introduces a new version of our TestMate® Particle Counter, TPM and the new Sensor Monitoring Unit, SMU. The new SMU allows live display of the TCM ISO code, TWS water concentration and fluid temperature. Besides displaying the key contamination data the SMU will also store the […]