Safety is a critical aspect to any fluid power system, not just from the basic level of keeping components plumbed properly, but also in overall levels of machine safeguarding. It is critical to evaluate the entire system, including the electrical portion, to minimize exposure to unnecessary risk. Systems are rated based on the weakest link […]

Engineering Basics

What are hydraulic rotary actuators?

Hydraulic rotary actuators are used for high torque, heavy-duty motion applications. They have high force capabilities, high power-per-unit weight and volume, good mechanical stiffness, and high dynamic response. They provide the heft for lifting, turning, indexing, clamping, mixing, bending, testing, and steering applications among others. Rotary actuators are compact and efficient, and produce high instantaneous […]

What are hydraulic replacement and rebuilds?

While the hydraulic and electric industries have become more complementary to each other, they have an entirely different kind of replacement market potential, due to: duty cycle frequency of use patterns of use maintenance needs Electrical products, particularly motors, are well understood and repaired by practically every repair house across the globe. This is not […]

What are hydraulic pressure transducers?

Pressure is termed as the force per given area required to stop a fluid expanding. Pressure transducers, which are a subset of pressure sensors, can be any number of devices which sample and record the pressure in a system. A pressure transducer is unique from gauge sensing in that it converts a pressure measurement into […]

What is hydraulics?

Hydraulics has been around in one form or another for thousands of years. When water was later used to irrigate and control water clocks, the water itself was accomplishing more work, turning waterwheels to mill flour or grind wood into pulp. Modern hydraulic systems are flourishing, as they have one particularly important thing going for […]

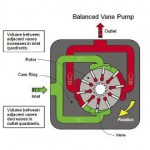

What are positive-displacement pumps?

Positive-displacement pumps, also called hydrostatic pumps, are used in fluid power motion control applications. They have a very small clearance between rotating and stationary parts. These pumps deliver a specific amount of fluid to the system for each revolution. Positive-displacement pumps can be further divided into two categories: Fixed- and variable-displacement. Fixed-delivery pumps provide a […]

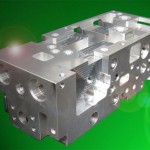

What are hydraulic manifolds?

This article was updated on July 15, 2016, with new images. A hydraulic manifold is a component that regulates fluid flow between pumps and actuators and other components in a hydraulic system. It could be compared to a switchboard in an electrical circuit, because it lets the operator control how much fluid flows between components of a hydraulic machinery. For example, in a backhoe […]

What are hydraulic hose couplings?

Improper selection or improper use of hoses, tubing, fittings, and assemblies can cause failures, personal injury, or property damage. Understanding the hose assembly and following the installation instructions provided by manufacturers will reduce these risks. Engineers looking to specify hose couplings need to consider a few things besides correct size. Will the couplings be reused […]

What are hydraulic cylinders?

Cylinders allow hydraulic systems to apply linear motion and force without mechanical gears or levers by transferring the pressure from fluid through a piston to the point of operation. Hydraulic cylinders are at work in both industrial applications (hydraulic presses, cranes, forges, packing machines), and mobile applications (agricultural machines, construction equipment, marine equipment). And, when […]

What is hydraulic hose?

A hydraulic hose is specifically designed to convey hydraulic fluid to or among hydraulic components, valves, actuators, and tools. It is typically flexible, often reinforced, and usually constructed with several layers of reinforcement since hydraulic systems frequently operate at high or very high pressures. Hydraulic hose is used in a variety of industrial hydraulic systems. […]