In the collection of hydraulic valve components, flow control valves are any device manufactured for the purpose of modifying the rate of fluid flow in a portion of a hydraulic circuit. Flow variability occurs through the adjustment of the effective orifice size inside the valve, and this is achieved through various techniques based upon the […]

Engineering Basics

How do relief valves work?

By Josh Cosford, Contributing Editor It seems like a question with an easy answer, but you’d be surprised how often people ask, “how do relief valves work?” We in the fluid power industry take our knowledge for granted, but each and every one of us was at some point ignorant of literally every hydraulic component […]

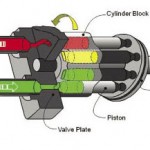

What is the difference between fixed and variable pumps?

For novices in the fluid power industry, lack of understanding between the fixed flow and variable flow pumping concepts is quite common. A hydraulic pump has one mission, and that is to transform incoming mechanical energy at its shaft into hydraulic energy capable of transferring force to actuators somewhere downstream. This transfer of force is […]

Telematics offers high-value solutions for industry

Telematics facilitates the exchange of rich data to and from mobile or remote machinery, helping to streamline maintenance and costs. Contributed by Carl Dyke, CD Industrial Group Inc. How can the owner of a fleet of cranes avoid the daily worries about whether the machines are being operated and maintained for safe performance? Is there […]

Hydraulic symbology 102: understanding basic fluid power schematics

By Josh Cosford, Contributing Editor Back in August of 2017, you saw my article Hydraulic symbology 101: Understanding basic fluid power schematics (read it here first, if you haven’t already). I covered basic constituent lines, shapes and their respective symbols. Due to space constraints, I left out some of the major components represented by symbols […]

How do I specify standard hydraulic manifolds?

By Josh Cosford, Contributing Editor The three most common ways to control hydraulic actuators are with lever valves, cartridge valves or sandwich valves. Lever valves are available as monoblock or stacked valves, and are primarily for directional control. Cartridge valves have nearly infinite possible combinations, but must be used with bodies or custom manifolds. Sandwich […]

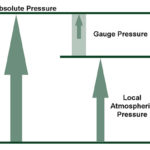

What does pressure really mean?

Pressure is simply the force applied perpendicular to the surface of an object per unit area over which that force is distributed. However, there are many ways to reference and identify pressure, which is largely dependent upon the application. In many applications, there is a common misconception that all pressure measurement needs to be absolute. […]

How do you calculate HPU pressure and flow requirements?

By Josh Cosford, Contributing Editor Before you select a pump for your HPU, you must calculate your pressure and flow requirements. To calculate flow required by your hydraulic pump, you must know the size and velocity of the actuators it will power. It is important to calculate the maximum flow required during simultaneous actuator operation, […]

What components make up hydraulic power units or HPUs?

By Josh Cosford, Contributing Editor Nearly every single hydraulic system shares one thing in common — they’re run by a hydraulic power unit. Although some units are multitaskers, like the engine on a tractor, most often they’re purpose-built for the single task of converting mechanical energy into hydraulic energy. The scope of a power unit […]

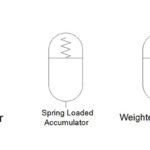

How do accumulators improve system performance?

Hydraulic accumulators are pressure vessels that store and discharge energy in the form of pressurized fluid. In essence, potential energy is stored in a compressed gas and released on demand to force oil from the accumulator and into the circuit. Here are some important benefits accumulators provide, and how they make hydraulic systems better. Energy […]