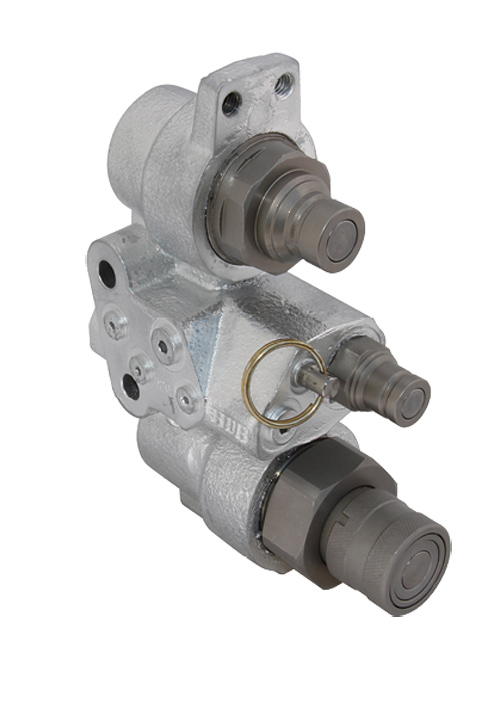

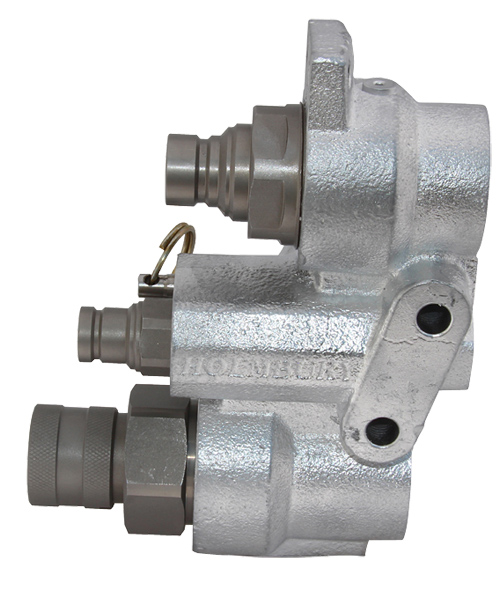

Operator safety and failing hydraulic systems have led to a new decompression block coupler from Holmbury. The HDB is designed for the quick change of hydraulic attachments for skid steer, compact and backhoe loaders—as well as compact utility vehicles. The decompression feature allows the operator to alleviate trapped pressure allowing for quick and easy connection of various attachments.

Holmbury will launch the coupler at ICUEE in Louisville next month. It is rated for maximum operating pressures of 350 bar and temperatures ranging from -25 to 100° C. It offers flow rates of 86 lpm at 2 bar ∆P and decompression force of 130 Nm at 275 bar trapped pressure.

Traditional construction equipment attachment change-out is usually done through a standard set of flat face couplers that connect to the auxiliary hydraulics. Relieving trapped pressure on the attachment (auxiliary side) was achieved by using a connect-under-pressure coupler, such as the company’s HCP series. However, explained Matt Mulder, Holmbury president, “The challenge is how to alleviate trapped pressure on the machine side. The problem is that every skid steer loader manufacturer has a different set of steps to relieve trapped pressure on the machine side. Unless this can be achieved, it is near impossible to connect an attachment because hydraulic oil does not compress.”

Holmbury developed the HDB when a major skid steer manufacturer was searching for a way to resolve a problem with its high-flow grapple attachment application. Mulder said the skid steer was using a competitor’s block coupler, which decompresses by pushing on the coupling. Due to the high-flow requirement, the rigidity of the hydraulic hose and the action of the grapple attachment, that block coupler decompression circuit was opening inadvertently, causing the hydraulic system to fail and ultimately creating an operator safety issue.

With the new HDB, the decompression valve cannot be inadvertently actuated during system operation. And it only takes a few seconds to make the change, whereas the traditional way to decompress a skid steer loader system can take several minutes or longer due to the various steps required to relieve trapped pressure within the machine side.

Mulder said that the mounting pattern is a direct interchange with Faster’s 4BD4FH and Stucchi’s Saturn block coupler series, which is installed on the end of the boom arm on the skid steer loader. He added that Faster is the leader in the market, and until recently, was the only hydraulic quick coupling manufacturer to offer a connect-under-pressure block coupler. The decompression function of the Holmbury HDB is different in that there is an external valve stem (push or pull) that when actuated, opens the machine hydraulic circuit back to tank. This immediately takes trapped system pressure to 0 psi.

Mulder said that the mounting pattern is a direct interchange with Faster’s 4BD4FH and Stucchi’s Saturn block coupler series, which is installed on the end of the boom arm on the skid steer loader. He added that Faster is the leader in the market, and until recently, was the only hydraulic quick coupling manufacturer to offer a connect-under-pressure block coupler. The decompression function of the Holmbury HDB is different in that there is an external valve stem (push or pull) that when actuated, opens the machine hydraulic circuit back to tank. This immediately takes trapped system pressure to 0 psi.

The Holmbury Decompression Block coupler features HQ series couplings with zinc nickel plating. It is fitted with Nitrile and PTFE seals. A pull activation feature prevents accidental system decompression.

All couplers are flat face and are designed to the 16028 Standard. Their low profile coupling design minimizes failures due to side-loading issues. They can be ordered in coupler arrangements of ½ in. for standard flow or ¾ in. for high flow applications. The case drain coupler is a standard 3⁄8 in. Finally, because the couplers allow for easy in-field replacement, they offer easy access for servicing of internal components and low cost.

Holmbury

holmburyusa.com

I’m looking for a block coupler for my Kubota SVL75, would you be able to steer me in the right direction as I’m in Dallas Texas

Jeff,

My name is Michael and I and the territory sales manager for Holmbury. Please email me at Michael@holmburyusa.com so that I can point you in the right direction. Thanks again for your interest.