Bar stock is used in various applications of fluid power, either as a mounting for other valve systems or simply for consolidation of plumbing. The bar stock itself is typically an alloy of either aluminum or ductile iron, and is manufactured in billets suitable for machining finished product. The most popular use is the bar stock manifold, which is a block of varying length drilled with passages, ports and bolt holes for mounting valve systems.

Bar stock is used in various applications of fluid power, either as a mounting for other valve systems or simply for consolidation of plumbing. The bar stock itself is typically an alloy of either aluminum or ductile iron, and is manufactured in billets suitable for machining finished product. The most popular use is the bar stock manifold, which is a block of varying length drilled with passages, ports and bolt holes for mounting valve systems.

Aluminum is a popular choice for bar stock material when system pressure is 3000 psi or less. Aluminum is easier to work with than ductile iron, and is also lower in physical mass and overall cost. However, when working pressure is higher than 3000 psi, iron is required to withstand the additional stress. Ductile iron is a cast alloy which is less brittle than standard cast iron, and is less expensive than steel; although forged steel is another option for bar stock, it is rarely used on less than the most extreme applications.

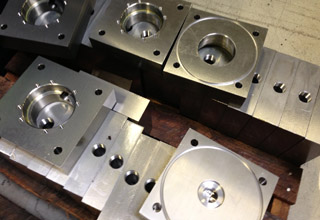

Whatever name you known them by best—ISO, cetop, NG6, D03 etc.—the industry standard modular stackable valves are the most common system of circuit construction, and they all require a manifold to interface with. A manifold for a D03 valve, for example, is around 3-in. tall and 3-in. deep, but can be as long as needed to mount any number of valve stacks. The manifold most often has pressure and tank drillings running its length. Each “station” of the manifold, where the valve mounts with four bolts, has four drillings mating up with the pressure and tank passages, as well as mating up with the work ports, which are drilled on side of the manifold in a vertical arrangement. Bar stock manifolds can be drilled as either parallel or series circuits, depending on the application.

Bar stock can be cut into smaller slices and drilled in similar arrangements to bar manifolds to create subplate mounts. The subplates allow one valve to mount atop, with four ports on each of the four sides. Bottom ported subplates are also available, but are rarely used. Bar manifolds have plenty of material to enable the addition of a relief valve cavity, but subplates have no such luxury of real estate. Both manifolds and subplates are available in sizes from D02 to D08, and many manifold accessories are available to help complete the hydraulic circuit, such as tapping plates, cover plates and gauge blocks.

Bar stock can also be used to clean up plumbing on machines by reducing the need for adapters and fittings. By drilling ports into a bar, a header or manifold can provide a junction to common feed or return lines, so that each tube or hose plumbs neatly into the same source. Manifolds and headers can reduce leak points, but also add a look of professionalism compared to a mess of tees and adapters. Bar stock is great for mounting components, such as test points, transducers or pressure switches. The bar material can also be anodized any color, or even just treated for corrosion resistance by clear anodizing for aluminum or nickel plating for ductile iron. Lastly, because bar stock is so commonly used in various applications, it is readily available through every fluid power distributor in North America.